13

13

•

Mark the workpiece with a non-permanent marker to make it easier to follow tracking

patterns or contour the metal.

•

Try using the lightest wheel pressure possible to shape the workpiece. Too much pressure

will crease or ruin the metal.

•

Light pressure is best for smoothing; higher pressure is best for rough shaping.

•

Consistent patterns and movements generally return consistent results.

Tracking Patterns

As metal passes between the upper and lower wheels, a "track" or shiny line is pressed into the

metal. Various tracking patterns can be used to shape workpieces depending upon their shape

or size.

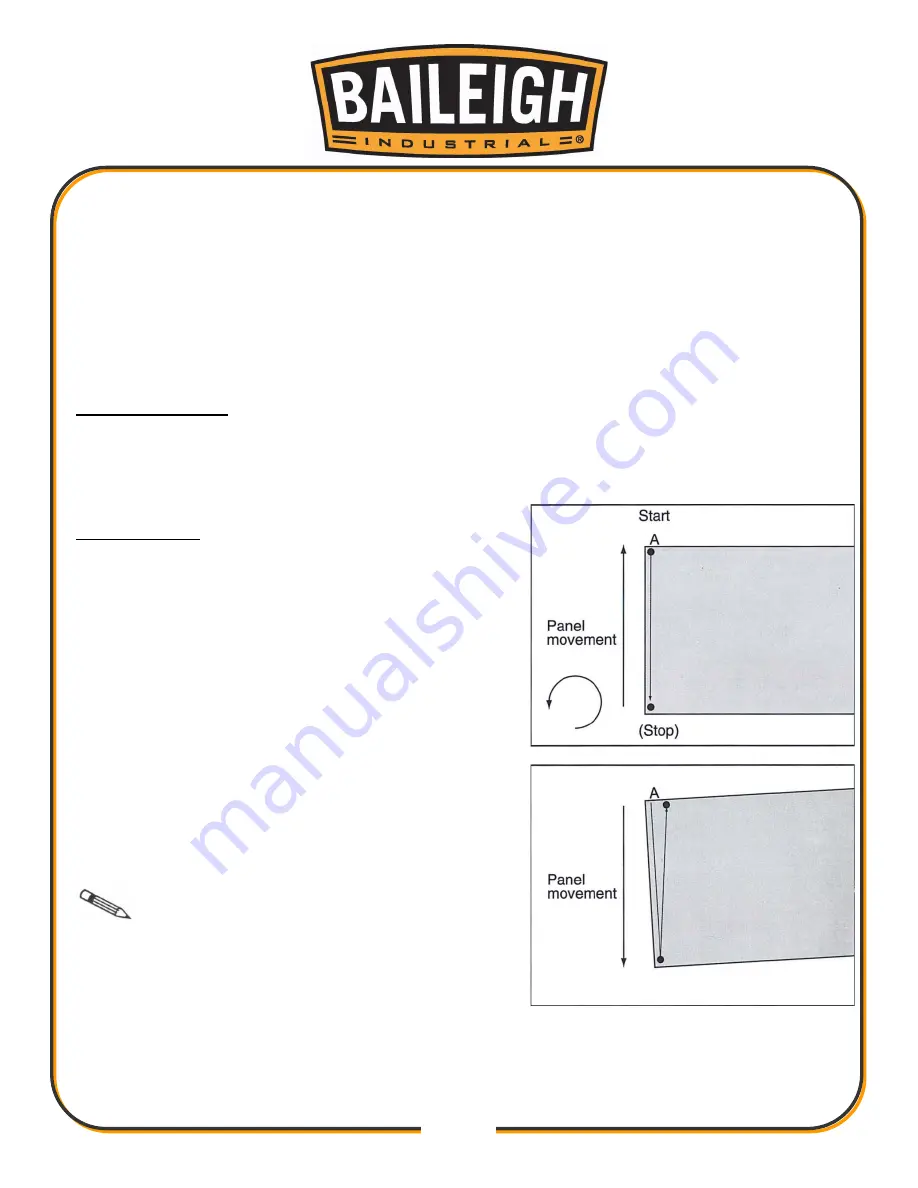

Zigzag Pattern

This pattern uses closely-spaced tracks to move from

one end of the material to the other. It can be used for

a variety of workpiece shapes.

1. Insert the workpiece between the wheels at point A,

and start rolling it along the edge. Left edge shown.

2. Push the workpiece forward to the stop point.

3. Turn the workpiece counterclockwise slightly.

4. Pull the workpiece back until it reaches the next

point near the far edge.

5. Turn the workpiece clockwise slightly.

6. Continue feeding the workpiece to the other side in

the same manner, following the pattern as shown.

Note

: Try keeping the tracks close to

each other.

Summary of Contents for EW-30

Page 1: ...OPERATOR S MANUAL ENGLISH WHEEL MODEL EW 30 B8870 2016 Baileigh Industrial Inc Rev 12 2016...

Page 21: ...19 19 FRAME ASSEMBLY...

Page 22: ...20 20 WHEEL ASSEMBLY...

Page 23: ...21 21 ADJUSTER ASSEMBLY...

Page 26: ...24 24 NOTES...

Page 27: ...25 25 NOTES...

Page 28: ...26 26 NOTES...

Page 29: ...27 27...