20

20

•

Improper connection of the equipment-grounding conductor can result in risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

•

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

•

Repair or replace damaged or worn cord immediately.

Power cord connection:

1. Unwrap the power cord and route the cord away from the machine toward the power supply.

a. Route the power cord so that it will NOT become entangled in the machine in any

way.

b. Route the cord to the power supply is a way that does

NOT create a trip hazard.

2. Connect the power cord to the power supply and check that the

power cord has not been damaged during installation.

3. Once hooked up, turn on the power supply and start the machine.

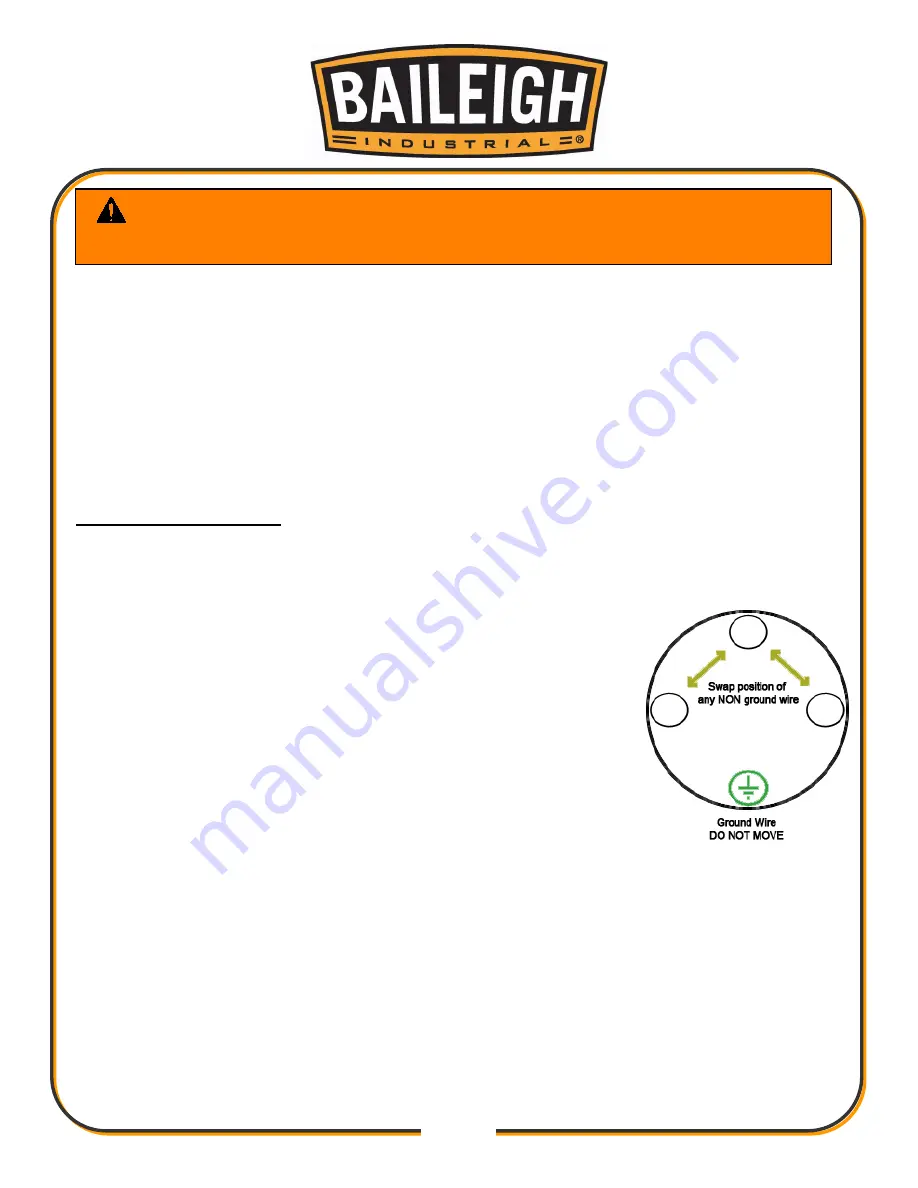

4. Check that the motor is running in the correct direction.

5. If not, cut the power to the machine. Swap the position of any two

of the three power wires; but DO NOT change the position of the

green grounding wire!

WARNING:

Make certain any receptacle in question is properly

grounded. If you are not sure, have a qualified electrician check the receptacle

.

Summary of Contents for HSP-176M-HD

Page 3: ...ELECTRICAL SCHEMATIC 38 Electrical Parts List 38 TROUBLESHOOTING 39 ...

Page 19: ...16 16 GETTING TO KNOW YOUR MACHINE A I G H L J B F K C E D ...

Page 30: ...27 27 Using the Machine Incorrect Correct ...

Page 31: ...28 28 Incorrect Correct ...

Page 37: ...34 34 RAM PARTS DIAGRAM ...

Page 39: ...36 36 HYDRAULIC PUMP PARTS DIAGRAM ...

Page 43: ...40 40 NOTES ...