9

9

25. Keep visitors a safe distance from the work area.

26.

Machines can eject

piece parts towards the operator. Know and avoid the conditions which

cause the piece part to kickback.

27.

Check

for damaged parts before using machinery. Check for binding or misaligned parts,

broken parts, loose bolts, or any other conditions which may impair the machines operation.

Repair or replace any damaged parts before operation.

28.

Do not stop

the spindle using your hand. Allow the spindle to stop on its own or in the case

of an emergency, use the spindle brake.

29.

Disconnect power

and make sure all moving parts have come to a complete stop before

changing cutting tools, starting any inspection, adjustment, or maintenance procedure.

30.

Properly secure

the cutting tool in the spindle before operating the machine.

31.

Do not remove

any warning signs.

32.

Check

safety equipment, such as safety covers, emergency stop buttons, safety mats,

railings, light booms, ramps, and warning signs.

33. Dressing material edges. Always chamfer and deburr all sharp edges.

34.

Warning

: The dust generated by certain woods and wood products can be injurious to your

health. Always operate machinery in well-ventilated areas and provide for proper dust

removal. Use a wood dust collection system whenever possible.

35.

Respiratory Protection.

Wear an approved dust mask or respirator while using this

machine. Continued exposure to wood dust can cause allergies or respiratory problems.

36.

Material Removal Rate.

Attempting to remove too much material at once can cause the

piece part to fly out of the lathe causing

severe bodily injury.

37.

NEVER

position fingers or thumbs near the infeed / outfeed rollers or cutterhead.

38. Long pieces of stock should

ALWAYS

be supported with some type of fixture.

39.

DO NOT

operate planer with dull or damaged blades.

40.

MAKE CERTAIN

that the planer is properly adjusted prior to use.

41.

DO NOT

try and remove excessive amounts of wood in one single pass.

42.

INSPECT

all stock before planing, ensuring that there are no foreign objects embedded in

the wood, loose knots, or knots that may become loose during operation.

43.

DO NOT

attempt to remove jams until power is disconnected and all moving parts have

come to a complete stop.

44.

MAKE SURE

that there is adequate operating space on both the infeed and outfeed sides of

the planer before operating.

45.

DO NOT

plane wood that is less than 7” (178mm) long or less than 1/8” (3.1mm) thick.

Summary of Contents for IP-1306

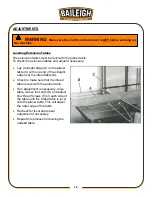

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...