26

26

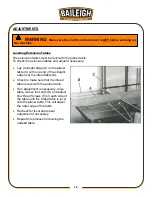

Thickness Planing

•

Thickness planing sizes the workpiece to a desired thickness, while at the same time

creating a smooth and level surface. The thickness of each cut will depend on the type of

wood, width of the workpiece, and condition of the lumber (i.e. dryness, grain composition,

straightness, etc).

•

Always make thin test cuts on a scrap piece of wood prior to performing final cuts.

General Tips and Guidelines

•

Thickness planing always works best when at least one side of the workpiece has a flat

surface. If both sides of the workpiece are rough, feed one face of the board through the

planer until the entire surface is flat.

•

ALWAYS plane both sides of the workpiece to reach the desired thickness.

•

DO NOT plane workpieces less than 1/8” thick, less than 3/4-in wide, or shorter than 7-in.

•

It is not recommended to

continuously use the planer at its maximum depth of cut (1/16”)

and at its full width (13”) as this will shorten the life of the motor.

•

Light cuts create a smoother finish than heavier cuts.

GENERAL RECOMMENDATIONS

•

Many variables determine suitable depth of cut, such as wood width, density, grain structure,

dampness, etc. For best results, use shallow cuts and multiple passes. Excessive depth of

cut will place undue strain upon the motor.

•

Use shallower cuts on wider workpieces.

•

A thickness planer works best when the lumber has at least one flat surface. Use a jointer to

create a flat surface. If this is not possible, make several passes of the same surface through

the planer until it is flat. Then flip the material over to plane the opposite surface.

•

Plane alternate sides until desired thickness is obtained. When half of the total cut has been

taken from each side, the board will have a uniform moisture content and additional drying

will not cause it to warp.

•

Make a test cut on scrap wood to verify thickness; check its accuracy before working on the

finished product.

•

Avoid knots. Heavily cross-grained wood makes knots hard. Knots can come loose and jam

the knives.

•

Do not plane dirty boards; dirt and small stones are abrasive and will wear out the knife

inserts and may become projectiles.

•

Do not plane boards less than 7 inches long. It is recommended that when planing short

boards you butt them end-to-end to avoid kickback and reduce snipe.

Summary of Contents for IP-1306

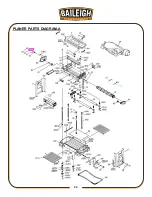

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

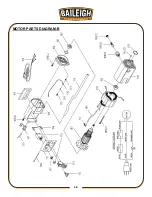

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...