32

32

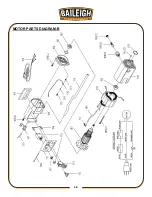

Gear Lubrication

The gears in the gear box should be lubricated periodically.

1. Facing the front of the machine, remove the raise/ lower

handle.

2. Remove the 9 screws holding the top cover on the

machine. 5 screws are located on top and 4 on the

upper sides. Remove the top cover.

3. On the left side panel, remove the 4 socket head screws

located around the bottom edge and remove the side

panel to expose the gearbox cover.

4. Remove the two screws (C) to remove the gear box

cover (B) and access the gear box.

5. Replace all covers, panels, and guards that you

removed once lubrication is complete.

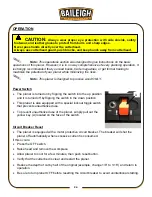

Brush Replacement

Brush life will vary depending on the load placed on the

motor. The brushes should be inspected every 20-30

hours of motor run time.

To inspect or replace:

1. Remove the brush holders, one of which is shown at

(A). The other is located in the same position on the

rear of the motor assembly. The Brush Holder can be

removed using a flat blade screwdriver.

2. Once the brush has been removed, inspect the carbon

(B), the spring (C), and the wire (D).

•

If the carbon of either brush is worn down to 3/16” or

less, both brushes should be replaced.

•

Also, if the spring or wire are burned or damaged in

any way, both brushes should be replaced.

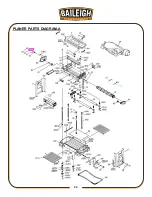

Summary of Contents for IP-1306

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...