43

43

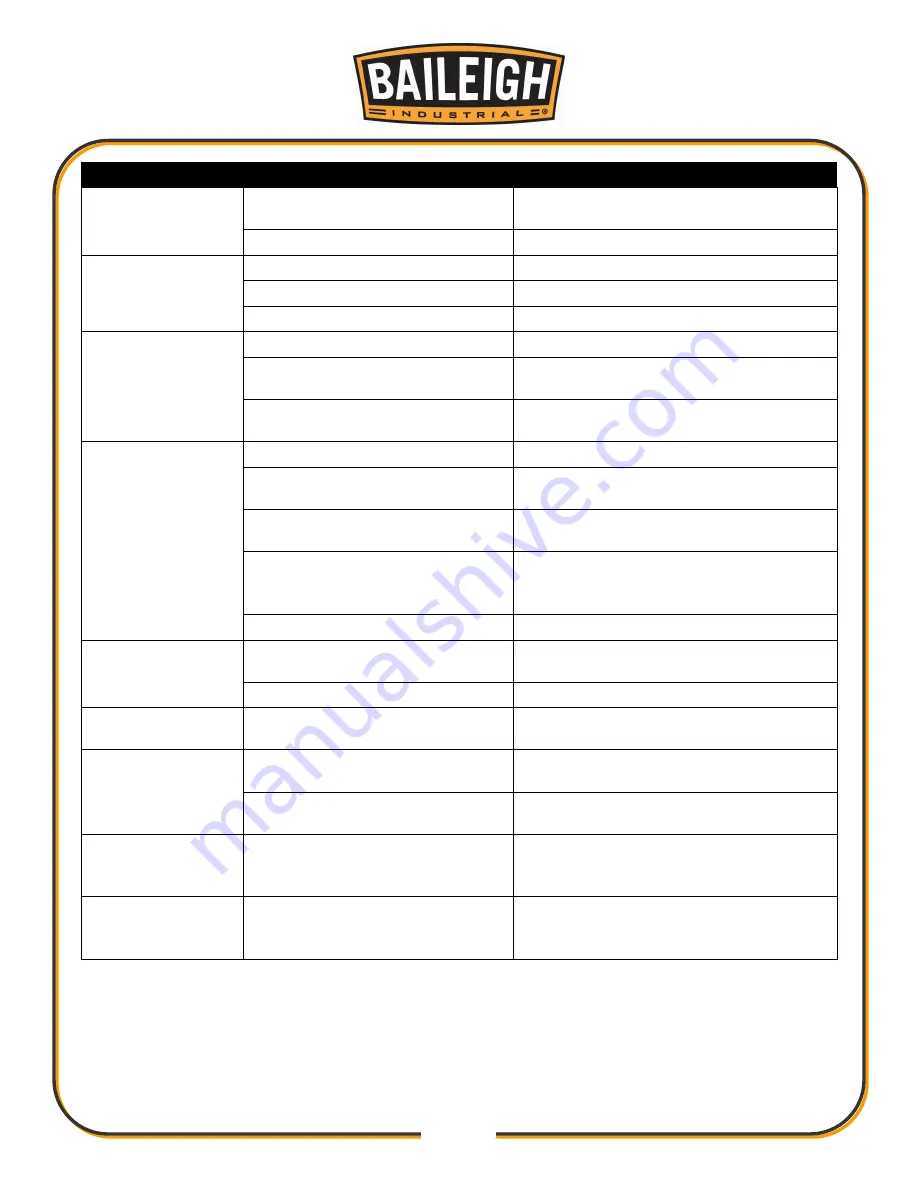

PROBLEM

LIKELY CAUSE

SOLUTION

Fuzzy grain.

Wood has high moisture

content.

Remove moisture by drying or use

different stock.

Dull knife inserts.

Rotate or replace knife inserts.

Torn grain.

Too heavy a cut.

Remove less material.

Knives cutting against grain.

Cut with the grain.

Dull knife inserts.

Rotate or replace knife inserts.

Rough/raised

grain.

Dull knife inserts.

Rotate or replace knife inserts.

Too heavy a cut.

Reduce depth of cut and make more

passes.

Wood has high moisture

content.

Remove moisture by drying or use

different stock.

Poor feeding of

lumber.

Excessive warpage of stock.

Use different stock.

Planer bed rough or dirty.

Clean pitch and residue; wax planer

bed.

Feed roller surfaces are dirty.

Clean feed rollers with cloth and mild

cleaner.

Dull knives, or debris building up

on cutterhead.

Clean cutterhead; rotate or replace

knife inserts; clean out dust hood if

being used.

Drive belt slipping or damaged.

Replace belt.

Uneven depth of

cut side to side.

Knife projection not uniform.

Inspect all knife inserts for positioning

and tightness.

Table not parallel to cutterhead. Contact Baileigh technical service.

Head difficult to

adjust.

Lack of lubrication on corner

posts and lead screws.

Lubricate posts and lead screws.

Head cannot be

lowered.

Thickness gauge is preventing

further movement.

Reset thickness gauge dial setting.

Buildup of debris on leadscrews

and/or columns.

Clean affected areas, and re-grease.

Board thickness

doesn’t match

thickness scale.

Thickness scale out of

adjustment.

Recalibrate thickness scale/cursor and

make test cuts.

Chain keeps

coming off

sprocket(s).

Chain or sprocket(s) are worn.

Inspect and replace as needed.

*Warning: Some corrections may require a qualified electrician.

Summary of Contents for IP-1306

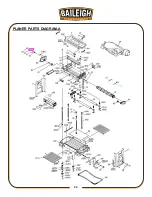

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

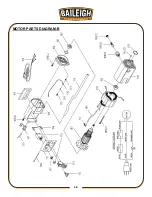

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...