27

27

•

For optimum planing performance, the depth of cut should be less than 1/16

”.

•

Recommended maximum depth of cut:

o

Hard/Softwood up to 5-

1/2” wide...........1/8”

o

Hard/Softwood 5-

1/2 to 13” wide.........1/16”

Ridges

•

Damaged or nicked knives can leave ridges along the length of a board.

•

Always inspect each board carefully before attempting to plane it.

•

Do not attempt to plane second-hand lumber with nails below the surface, painted wood,

plywood, hardboard, wood with a glue bead, or any material other than solid wood.

Planing Glued-Up Boards

This planer is designed for planing solid wood. Other material, including glue, will dull or

damage the knives. However, when you need to ‘true-up” glued-together stock, follow these

suggestions.

•

As you glue the stock, scrub off all the glue on the surface with a wet rag. This prevents glue

beads from forming on the wood surface. Allow the glue to dry at least 24 hours. Check the

surface for any glue that you missed and remove with a scraper, chisel, or sander.

•

Set the cutterhead for a shallow depth of cut. When you are finished planing the glued-up

board, unplug the planer and check planer knives for built-up pitch or other signs of wear.

WARNING:

Do not attempt to plane second-hand lumber, painted or

varnished wood, plywood or particle board. These materials can damage planer

knives. Failure to comply may cause serious injury.

NOTICE:

Glued-up stock must dry at least 24 hours before being planed. Failure to comply

may cause the stock to separate in the planer, leading to kickback and serious injury.

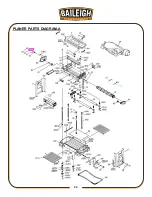

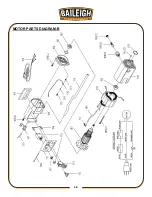

Summary of Contents for IP-1306

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...