31

31

LUBRICATION AND MAINTENANCE

Daily Maintenance

•

Do a general cleaning by removing dust and chips from the machine.

•

Check and tighten any loose mounting bolts.

•

Sharpen or replace any worn or damaged tooling.

•

Inspect the power plug and cord.

•

Keep area around machine clear of debris.

•

Check for any unsafe conditions and fix immediately.

•

Check that all nuts and bolts are properly tightened.

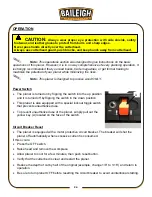

Cleaning

Sawdust buildup and other debris can cause the machine to plane incorrectly. Periodic cleaning

and waxing is needed for accurate precision planning. Any moving parts should be cleaned

regularly with penetrating oil and lubricated with a light coating of medium weight machine oil.

With the machine unplugged, blow off motor with low pressure air to remove dust or dirt. Air

pressure above 50 P.S.I. should not be used as high-pressured air may damage insulation. The

operator should always wear a respirator and eye protection when using compressed air. Do not

allow chips and dust to accumulate under the machine. Keep area clean and in safe order.

Note: When cleaning chips and debris from the machine, use a brush and a shop

vacuum. DO NOT blow off the machine with compressed air. The force of the compressed air

may force chips into critical mechanisms or may inflict injury to yourself or others.

Periodically clean, wax, and buff the tables. This will aid in the prevention of improper feeding of

the work piece.

Hardware Tightness

Periodically check all clamps, nuts, bolts, and screws, for tightness and condition. Stop the

machine and recheck the cutterhead screw and knives, or tips, for tightness after about 50

hours of operation.

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

Summary of Contents for IP-1306

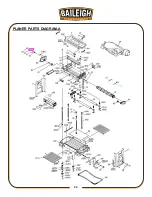

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

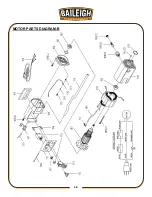

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...