15

15

MATERIAL SELECTION

When selecting materials keep these instructions in mind:

•

Material must be clean and dry. (without oil)

•

Material should have a smooth surface so it processes easily.

•

Dimensional properties of material must be consistent and not exceed the machine capacity

values.

•

Chemical structure of material must be consistent.

•

Buy certificated steel from the same vendor when possible.

LUBRICATION AND MAINTENANCE

•

Check daily for any unsafe conditions and fix immediately.

•

Check that all nuts and bolts are properly tightened.

•

On a weekly basis clean the machine and the area around it.

•

Lubricate threaded components and sliding devices.

•

Apply rust inhibitive lubricant to all non-painted surfaces.

•

Grease the fittings every month with two pumps from a standard grease gun.

•

Check for any worn or damaged parts and replace immediately.

•

Check and fill oil cup as needed. Use AW-46 hydraulic oil.

Note

: Proper maintenance can increase the life expectancy of your machine.

CAUTION:

It must be determined by the customer that materials being

processed through the machine are NOT potentially hazardous to operator or

personnel working nearby.

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

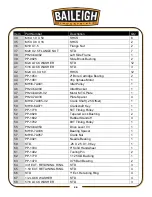

Summary of Contents for PH-28HD-VS

Page 1: ...OPERATOR S MANUAL POWER HAMMER MODEL PH 28HD VS B9045 2018 Baileigh Industrial Inc Rev 02 2018...

Page 18: ...16 16 PLATE ASSEMBLY...

Page 19: ...17 17 UPPER LOWER RAM ASSEMBLY...

Page 20: ...18 18 SPROCKET ASSEMBLY...

Page 21: ...19 19 SPRING ASSEMBLY...

Page 22: ...20 20 LEVER ASSEMBLY...

Page 23: ...21 21 SLIDE STROKE ASSEMBLY...

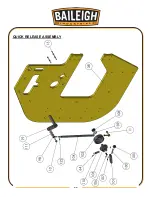

Page 24: ...22 22 QUICK RELEASE ASSEMBLY...

Page 25: ...23 23 V BELT ASSEMBLY POST...

Page 26: ...24 24 GUARD AND CONTROL BOX ASSEMBLY...

Page 33: ...31 31 NOTES...

Page 34: ...32 32 NOTES...

Page 35: ...33 33...

Page 36: ...34 34...