9

9

UNPACKING AND CHECKING CONTENTS

Your Baileigh machine is shipped complete in one package. Separate all parts from the packing

material and check each item carefully. Make certain all items are accounted for before

discarding any packing material.

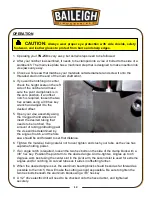

Cleaning

Your machine may be shipped with a rustproof waxy coating and/or grease on the exposed

unpainted metal surfaces. Fully and completely remove this protective coating using a

degreaser or solvent cleaner. Moving items will need to be moved along their travel path to

allow for cleaning the entire surface. For a more thorough cleaning, some parts will occasionally

have to be removed.

DO NOT USE

acetone or brake cleaner as they may damage painted

surfaces.

Follow manufacturer’s label instructions when using any type of cleaning product. After cleaning,

wipe unpainted metal surfaces with a light coating of quality oil or grease for protection.

Important: This waxy coating is NOT a lubricant and will cause the machine to

stick and lose performance as the coating continues to dry

WARNING:

SUFFOCATION HAZARD! Immediately discard any plastic

bags and packing materials to eliminate choking and suffocation hazards to children

and animals.

If any parts are missing, do not plug in the power cable, or turn the power switch on

until the missing parts are obtained and installed correctly.

WARNING:

DO NOT USE gasoline or other petroleum products to clean

the machine. They have low flash points and can explode or cause fire.

CAUTION:

When using cleaning solvents work in a well-ventilated area.

Many cleaning solvents are toxic if inhaled.

GAS

Summary of Contents for TN-250

Page 17: ...15 15 PARTS IDENTIFICATION DRAWING ...

Page 18: ...16 16 ...