41

41

•

Check the drive belt for tightness. It should be snug but not overly tight. Readjust or replace

belt as required.

•

Use a mill file to remove any nicks or dings from the infeed or outfeed tables.

Note

: Proper maintenance can increase the life expectancy of your machine.

Cleaning

Cleaning the saw is relatively easy. Vacuum excess wood chips and sawdust and wipe off the

remaining dust with a dry cloth. If any resin has built up, use a resin dissolving cleaner to

remove it.

After cleaning, treat all unpainted cast iron and steel with a non-staining lubricant.

Occasionally it will become necessary to clean the internal parts with more than a vacuum. To

do this, remove the tabletop and clean the internal parts with resin/pitch dissolver or mineral

spirits and a stiff wire brush or steel wool.

Make sure the internal workings are dry before using the saw again, so that wood dust will not

accumulate. If any essential lubrication is removed during cleaning, re-lubricate those areas.

Lubrication

The table saw has sealed lubricated bearings in the motor housing and the arbor assembly, they

will not require any additional lubrication. Use a wire brush to clean off the worm gears and

trunnions and apply a white lithium grease to keep them lubricated.

Changing the Belt

1. Disconnect the machine from the power source,

unplug.

1. Lower the blade to its lowest point.

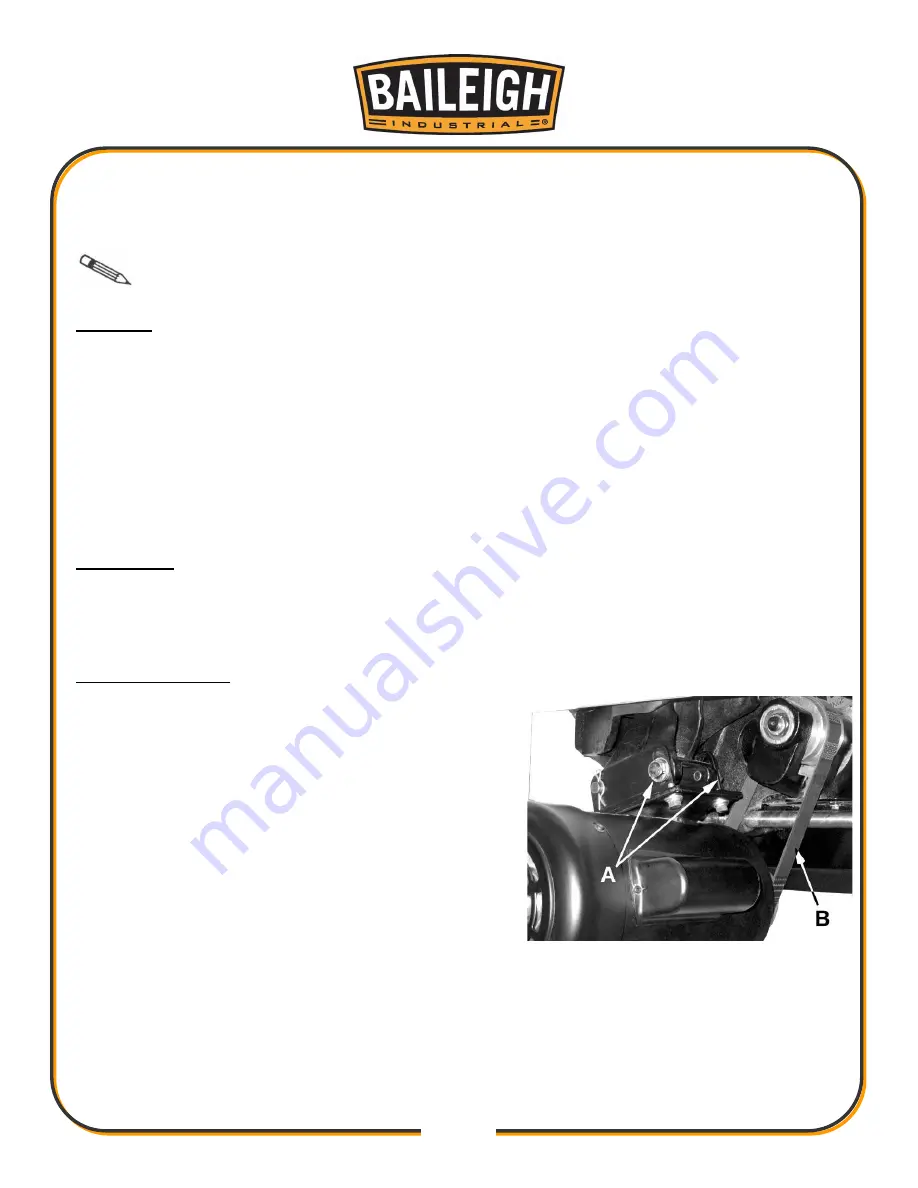

2. Loosen two hex cap bolts (A).

3. Take the tension off of the belt (B) by lifting up on

the motor.

4. Remove the belt from the arbor and motor pulleys.

5. Replace and tension the belt. The weight of the

motor should apply enough tension to the belt.

Tighten the hex cap bolts (A).

6. Check the belt tension after the saw has been used for a few hours. Adjust as necessary.