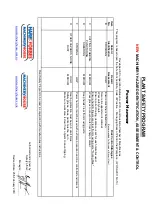

Power Hammer Safety Instructions

1. Maintenance.

Make sure the Power Hammer is

turned off and disconnect electrical power before any

inspection, adjustment or maintenance is carried out.

2. Power Hammer Condition.

Power Hammer

must be maintained for proper working condition.

Never operate a Power Hammer that has damaged

or worn parts. Scheduled routine maintenance should

performed on a scheduled basis.

3. Leaving a Power Hammer Unattended.

Always turn the Power Hammer off before leaving the

Power Hammer. Do not leave Power Hammer running

unattended for any reason.

4. Hand Hazard.

Keep hands and fingers clear from

moving parts. Serious injury can occur if hand or

finger tips get pinched between tooling.

5. Gloves & Glasses.

Always wear leather gloves

and approved safety glasses when using this machine.

6. Avoiding Entanglement.

Tie up long hair and

use the correct hair nets to avoid any entanglement

with moving parts.

7. Understand the machines controls.

Make

sure you understand the use and operation of all

controls.

8. Warning Labels.

Take note of any warning labels

on the machine and do not remove them.

9. Overloading Machine.

Do not exceed the rated

capacity of the Power Hammer. Please refer to the

manual for capacities.

10. Hearing Protection and Hazards.

Always

wear hearing protection as noise generated from

machine and workpiece vibration can cause

permanent hearing loss over time.

11. Eye Protection.

Always wear safety glasses

when using and cleaning this machine.

12. Work Area Hazards.

Keep the area around

the Power Hammer clean from oil, tools, chips.

Pay attention to other persons in the area and

know what is going on around the area to ensure

unintended accidents.

13. Level Machine.

Level the machine on a flat

concrete surface by using a spirit level.

14. Call For Help.

If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Machinery House

requires you to read this entire Manual before using this machine.

Summary of Contents for B8935

Page 1: ...OPERATOR S MANUAL POWER HAMMER MODEL MH 19 B8935 2015 Baileigh Industrial Inc Rev 04 2015...

Page 19: ...17 17 PARTS DIAGRAM Stand Frame Assembly Parts Diagram...

Page 20: ...18 18 Slide Block Assembly Parts Diagram...

Page 21: ...19 19 Pulley Assembly Parts Diagram...

Page 22: ...20 20 Crankshaft Assembly Parts Diagram...

Page 23: ...21 21 Clevis Shaft Assembly Parts Diagram...

Page 24: ...22 22 Bell Crank Assembly Parts Diagram...

Page 25: ...23 23 Main Lever Assembly Parts Diagram...

Page 26: ...24 24 Height Adjustment Assembly Parts Diagram...

Page 27: ...25 25 Left Hand Frame Assembly Parts Diagram...

Page 28: ...26 26 Guard Assembly Parts Diagram...

Page 35: ...33 33 NOTES...

Page 36: ...34 34...