22

22

Lubrication

Lubrication of the grinder is not required. Bearings are pre-lubricated and sealed.

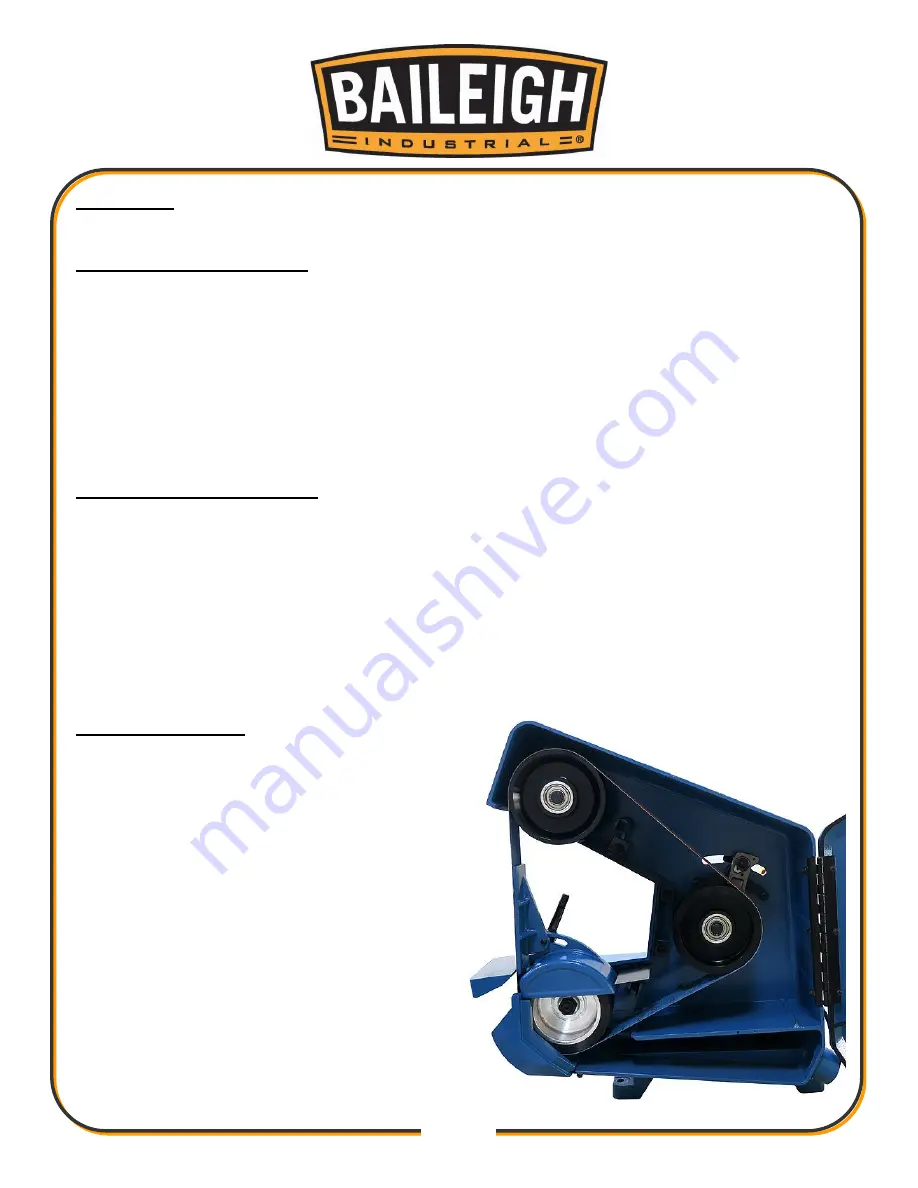

Abrasive Belt Replacement

•

Disconnect machine from power source.

•

Open side cover, and open dust cover by unscrewing dust cover screw.

•

De-tension and slip belt off wheels.

•

Install new belt around wheels, tension, and test tracking. Make further adjustments as

needed.

•

Close all covers before operating.

Contact Wheel Replacement

•

Disconnect machine from power source.

•

Open side cover and dust cover and remove abrasive belt.

•

Loosen and remove hex nut and flange washer, and slide contact wheel off spindle.

•

Install new wheel. Reinstall flange washer and hex nut and tighten.

•

Install abrasive belt, tension, and check tracking.

•

Close all covers before operating.

V-Belt Replacement

•

Disconnect machine from power source.

•

Remove four button head screws and open

motor shroud.

•

Remove two screws from pulley cover

(access through housing) and remove

pulley cover.

•

Slide motor forward to loosen belt and slip

belt off pulleys.

•

Install new belt and slide motor back to

tension it.

•

Tighten motor mount screws.

•

Secure all covers and screws.

Summary of Contents for BG-142S

Page 18: ...16 16 GETTING TO KNOW YOUR MACHINE ...

Page 27: ...25 25 MOTOR AND BASE ASSEMBLY EXPLODED VIEW BG 142S 248S 260S ...

Page 32: ...30 30 BELT AND HOUSING ASSEMBLY EXPLODED VIEW BG 142S ...

Page 33: ...31 31 ...

Page 37: ...35 35 BELT AND HOUSING ASSEMBLY EXPLODED VIEW BG 248S ...

Page 38: ...36 36 ...

Page 42: ...40 40 BELT AND HOUSING ASSEMBLY EXPLODED VIEW BG 260S ...

Page 43: ...41 41 ...