34

34

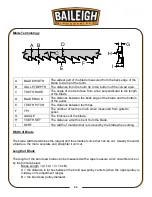

Blade Guide Bearing Adjustment

IMPORTANT:

This is the most important adjustment on your saw. It is impossible

to get satisfactory work from your saw if the blade guides are not properly adjusted. This saw

has been adjusted and power tested before leaving the factory to insure proper setting. If the

guides do get out of adjustment, it is extremely important to re-adjust immediately. An

improperly adjusted blade will not cut straight and serious blade damage may result. It is always

best to try a new blade to see if this will correct poor cutting before beginning to adjust the blade

guide bearings. If the blade becomes dull on one side and not the other, for example, it will

begin cutting crooked. A blade change will correct this problem; the guide adjustment will not. If

a new blade does not correct the problem, check the clearance between the blade and guides.

Clearance should be from just touching to .001”.

The inner guide bearing is fixed and cannot be adjusted. The outer guide bearing is mounted to

an eccentric bushing and can be adjusted.

1. Loosen the nut while holding the bolt with an allen wrench.

2. Position the eccentric by turning the bolt to the desired position of clearance.

3. Tighten the nut.

4. Adjust the second blade guide bearing in the same manner.

Front bearing assembly

Rear bearing assembly

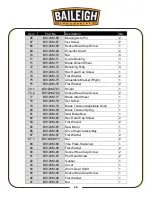

Summary of Contents for BS-128M

Page 3: ...SAW VISE AND BASE PARTS DIAGRAM 37 Parts List 38 ELECTRICAL SCHEMATIC 43 TROUBLESHOOTING 44...

Page 15: ...12 12 GETTING TO KNOW YOUR MACHINE S R Q P O N M L K J I H G F E D C B A...

Page 29: ...26 26...

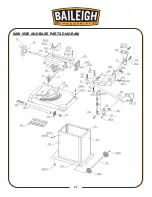

Page 39: ...36 36 SAW BOW PARTS DIAGRAM...

Page 40: ...37 37 SAW VISE AND BASE PARTS DIAGRAM...

Page 46: ...43 43 ELECTRICAL SCHEMATIC...

Page 50: ...47 47 NOTES...

Page 51: ...48 48 NOTES...