41

41

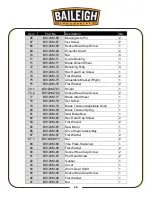

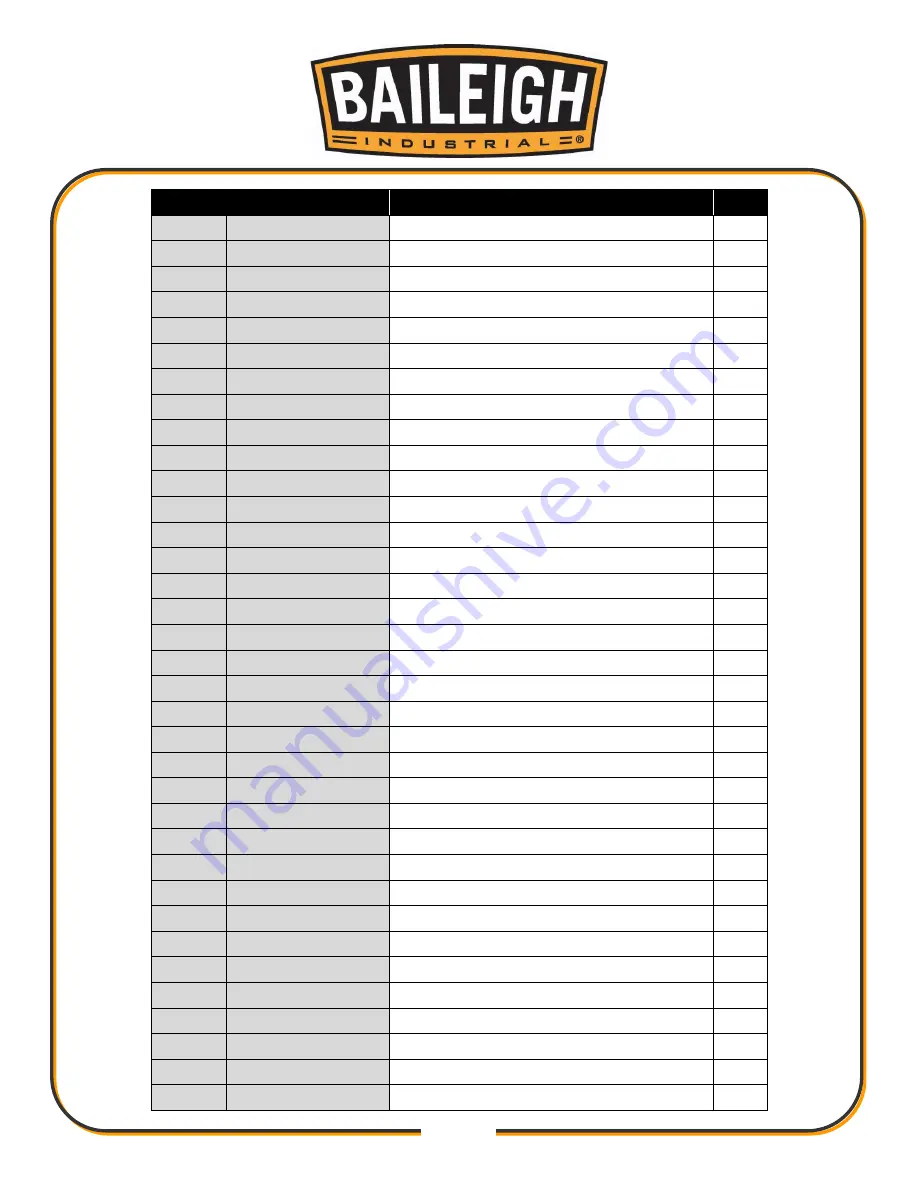

Item

Part No.

Description

Qty

98

BS128M-98

Hex Head Cap Screw

1

99

BS128M-99

Nut

1

101

BS128M-101

Driven Sheave Assembly

1

102

BS128M-102

T-Neck Pivot Bolt

1

103

BS128M-103

Blade Tension Sliding Bracket

1

104

BS128M-104

Flat Washer

2

105

BS128M-105

Pivot

1

106

BS128M-106

Socket Head Cap Screw

1

106.1

BS128M-106.1

Flat Washer

1

107

BS128M-107

Bearing

2

108

BS128M-108

Shaft Block

1

109

BS128M-109

Blade Tension Sliding Guide

2

110

BS128M-110

Anchor

1

110.1

BS128M-110.1

Mounting Angle

1

110.2

BS128M-110.2

Socket Head Cap Screw

2

110.3

BS128M-110.3

Block

1

110-1

BS128M-110-1

Belt Cover

1

111

BS128M-111

Socket Head Cap Screw

1

111.1

BS128M-111.1

Washer

1

111.2

BS128M-111.2

Nut

1

112

BS128M-112

Drive Belt

1

114

BS128M-114

Socket Head Cap Screw

2

115

BS128M-115

Flat Washer

2

116

BS128M-116

Spacer Plate

1

117

BS128M-117

Cylinder Mounting Block

1

118

BS128M-118

Socket Head Cap Screw

3

119

BS128M-119

Set Screw

1

125.2

BS128M-125.2

Rivet

2

126

BS128M-126

Hex Head Cap Screw

4

127

BS128M-127

Flat Washer

4

128

BS128M-128

Base Panel, Material Outfeed Side

1

129

BS128M-129

Socket Head Cap Screw

16

130

BS128M-130

Flat Washer

16

131

BS128M-131

Base Panel, Wheel End

1

132

BS128M-132

Base Panel, Material Infeed Side

1

Summary of Contents for BS-128M

Page 3: ...SAW VISE AND BASE PARTS DIAGRAM 37 Parts List 38 ELECTRICAL SCHEMATIC 43 TROUBLESHOOTING 44...

Page 15: ...12 12 GETTING TO KNOW YOUR MACHINE S R Q P O N M L K J I H G F E D C B A...

Page 29: ...26 26...

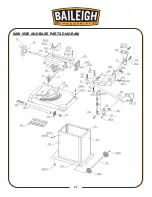

Page 39: ...36 36 SAW BOW PARTS DIAGRAM...

Page 40: ...37 37 SAW VISE AND BASE PARTS DIAGRAM...

Page 46: ...43 43 ELECTRICAL SCHEMATIC...

Page 50: ...47 47 NOTES...

Page 51: ...48 48 NOTES...