17

17

Improper connection of the equipment-grounding conductor can result in risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Repair or replace damaged or worn cord immediately.

Connecting Power Supply

You may either install a plug or “hard-wire” the Planer directly to a control panel.

If you are connecting a plug, use a proper UL/CSA listed 3-pole, 3-wire grounding plug

suitable for 220 Volt operation.

If the Planer is to be hard-wired to a panel, make sure a disconnect switch is readily

available for the operator.

During hard-wiring of the Planer, make sure the fuses have been removed or the breakers

have been tripped in the circuit to which the Planer will be connected. Place a warning

placard on the fuse holder or circuit breaker to prevent it being turned on while the machine

is being wired.

Always

follow proper lockout /tagout procedures.

1. Lock power out to the circuit that will provide power

to the machine.

2. Remove the electrical box cover.

3. Route the electrical cable into the electrical box.

a. Route the power cord so that it will NOT become

entangled in the machine in any way.

b. Route the power cord so that it will NOT create a

trip hazard.

4. Using wire nuts, connect the three power wires to

the wire leads

Black, Red, & White

. Connect the

ground wire (typically green) to the

Green

lead.

WARNING:

In all cases, make certain the receptacle in question is

properly grounded. If you are not sure, have a qualified electrician check the

receptacle

.

Summary of Contents for IP-2008-HD

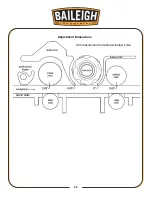

Page 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Page 42: ...39 39 6 Loosen Nut on motor bracket 7 Remove belt 8 Remove cutterhead pulley...

Page 46: ...43 43...

Page 50: ...47 47 PARTS DIAGRAM...

Page 51: ...48 48...

Page 52: ...49 49...

Page 53: ...50 50...

Page 54: ...51 51...