19

19

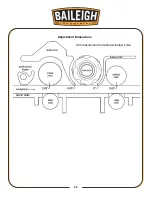

OPERATING CONTROLS

Emergency Stop (A): There are two emergency stops.

One located on the front (material in feed) left of the

planer and the other is located on the rear (material

out feed) right of the planer. Press either or both

emergency stop buttons to stop the machine. Twist the

cap 1/4 turn to release and reset the emergency stop.

Both emergency stops must be in the released

position to allow the machine to operate.

Key Switch (B): The key switch is the On/Off switch.

With power connected and the table and blade area

clear of any material or objects, to the key switch 1/4

turn clockwise

RAISING AND LOWERING TABLE

Turn the handwheel (C) clockwise to raise the table.

One revolution equals 1/16"

(.0625” [1.5875mm]).

CHANGING FEED RATE

The planer has two selectable feed speeds that feed

stock at 22 and 28 feet per minute (6.7 and 8.5mpm).

To adjust speed, move lever (D) until it clicks into

place.

When the shifter knob (D), is pushed all the way in as

shown, the feed roll speed will be 28 feet per minute.

When the shifter knob is pulled all the way out, the

feed roll speed will be 22 feet per minute. When the

shifter knob is in the center (neutral) position, the feed

rolls are disengaged and the machine will stop

feeding.

Important:

Change feed speed only while the feed system is RUNNING!

TABLE ROLLER ADJUSTMENT

Loosen the handle (E) and move the table rollers up, or down by raising, or lowering the handle.

When you reach the desired position tighten the handle.

The rollers are usually set higher when planing rough stock. When planing smooth stock the

table rollers should be set only slightly above, or flush with the table.

A

B

E

C

D

Summary of Contents for IP-2008-HD

Page 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Page 42: ...39 39 6 Loosen Nut on motor bracket 7 Remove belt 8 Remove cutterhead pulley...

Page 46: ...43 43...

Page 50: ...47 47 PARTS DIAGRAM...

Page 51: ...48 48...

Page 52: ...49 49...

Page 53: ...50 50...

Page 54: ...51 51...