20

20

CALIBRATING THE THICKNESS SCALE

The following sections will describe the use of a calibrating board. The calibrating board should

be made of a hardwood and have one side that has been run through a jointer.

1. With the planer turned "OFF - cutterhead NOT spinning", place your calibrating board jointed

surface down on the table and slide it into the machine.

2. Use the handwheel (A, Fig. 6) to raise the table so that the in-feed roller is about 1/16" above

the calibrating board.

3. Remove calibrating board from planer and turn the planer "ON".

4. Turn the handwheel clockwise one complete revolution to raise the table and run the

calibrating board through the planer.

5. Repeat Step 4 until the planer removes the entire top surface of your calibrating board.

6. Measure the thickness of the board using a pair of calipers.

7. Adjust the pointer (E, Figure 6) so that it reads the measured thickness by loosening the

screw that holds it in place.

Summary of Contents for IP-2008-HD

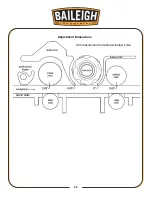

Page 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Page 42: ...39 39 6 Loosen Nut on motor bracket 7 Remove belt 8 Remove cutterhead pulley...

Page 46: ...43 43...

Page 50: ...47 47 PARTS DIAGRAM...

Page 51: ...48 48...

Page 52: ...49 49...

Page 53: ...50 50...

Page 54: ...51 51...