27

27

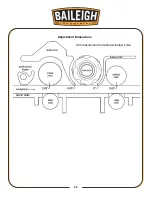

Feed Roll Speed Control

IMPORTANT: ONLY CHANGE FEED

ROLL SPEEDS WHEN THE MACHINE IS

RUNNING.

Two feed roll speeds of 28 and 22 feet per minute

are provided with your planer. Generally speaking,

the slower feed rate provides more cuts per inch,

thus a finer, smoother finish of the workpiece is

obtained. A good rule to follow would be to operate

the machine at the faster feed rate for general planing and switch to the slower feed rate for the

final finished dimension of the workpiece. When planing wide stock (wider than 8") particularly in

hard wood, the slower feed roll speed is more desirable as there is less strain on the motor and

a better finish is obtained since there are more cuts per inch of stock in length.

When the shifter knob, is pushed all the way in as shown, the feed roll speed will be 28 feet

per minute.

When the shifter knob is pulled all the way out, the feed roll speed will be 22 feet per minute.

When the shifter knob is in the center (neutral) position, the feed rolls are disengaged and

the machine will stop feeding.

Feed Roll Pressure Adjustment

The pressure of the roller will depend on the

pressure set by the spring and screws.

1. To adjust the pressure, loosen or tight the four

adjust screw and springs (A) on both ends of

the feed roller.

2. To ensure the best cutting results make sure

both side are at the same lever pressure.

Summary of Contents for IP-2008-HD

Page 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Page 42: ...39 39 6 Loosen Nut on motor bracket 7 Remove belt 8 Remove cutterhead pulley...

Page 46: ...43 43...

Page 50: ...47 47 PARTS DIAGRAM...

Page 51: ...48 48...

Page 52: ...49 49...

Page 53: ...50 50...

Page 54: ...51 51...