30

30

Adjusting Infeed Roller and Outfeed Roller

Before Adjust rollers, there must be made to check

position of the cutterhead used a thickness gauge

0.5mm and homemade gauge block.

Turn the handwheel to make the table upward then

place thickness gauge under the cutter, there are

must be a thickness gauge of 0.5mm to get the

correct position.

IMPORTANT: Do not move the table or

make any adjustments.

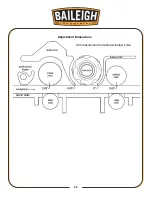

Checking Infeed Roller

Place gauge block under the infeed roller.

Loosen Nut (A) turn screw (B) that will make the

feed roller moves upward or downward. Then

making roller touch the top of gauge block. When

adjustment have been finished, tighten nut (A)

and screw (B). It is the same way to check the

height of the other end. (Fig. 15)

Checking Outfeed Roller

Place gauge block under the outfeed roller.

Loosen Nut (A) turn screw (B) that will allow for

the feed roller moves upward or downward. Then

making roller touch the top of gauge block. When

adjustment have been finished, tighten nut (A)

and screw (B). It is the same way to check the

height of the other end. (Fig. 16)

Summary of Contents for IP-2008-HD

Page 28: ...25 25 All measurements are shown below knife Adjustment Dimensions...

Page 42: ...39 39 6 Loosen Nut on motor bracket 7 Remove belt 8 Remove cutterhead pulley...

Page 46: ...43 43...

Page 50: ...47 47 PARTS DIAGRAM...

Page 51: ...48 48...

Page 52: ...49 49...

Page 53: ...50 50...

Page 54: ...51 51...