25

25

LUBRICATION

This planer features factory-sealed bearings. Sealed bearing requires no lubrication during its

lifetime. Should a bearing fail, your planer will probably develop a noticeable rumble/vibration

which will increase when the machine is put under load.

Proper lubrication of other machine components is essential for long life and trouble-free

operation. Below is a list of components that require periodic lubrication. Schedules are based

on daily use. Adjust accordingly for your level of use.

Parts Lubrication Required

No. Position

Grease

Oil

1

Worm Gear

Yes

No

2

Gear Box

No

Yes

3

Chain

Yes

No

4

Chain

Yes

No

5

Chain

Yes

No

6

Bracket

No

Yes

7

Lead Screw

Yes

No

8

Column Clean & Oil

No

Yes

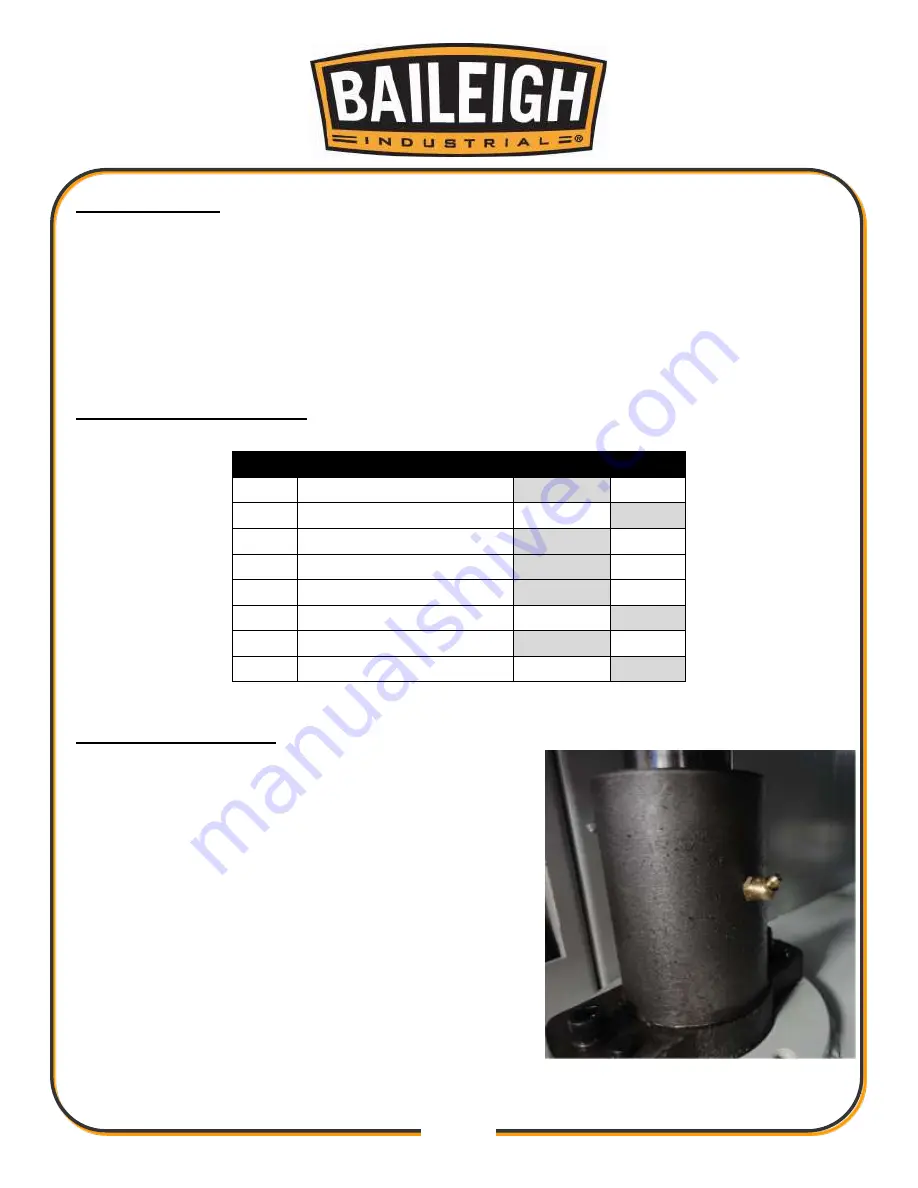

Table Elevation Screws

Use a light grease to lubricate the four elevation screws.

1. To access and lubricate the table elevation screws,

safely turn on power and raise the table all the way

up.

2. UNPLUG OR DISCONNECT PLANER FROM

POWER SOURCE AND LOCK OUT POWER.

3. Remove the front and rear cover below the table.

4. Use grease gun to pump 1 - 2 shots of grease into

the grease fitting attached on table elevation

columns.

Fig. 11

Summary of Contents for IP-2511-HD

Page 39: ...36 36 ELECTRICAL SCHEMATIC...

Page 40: ...37 37...

Page 41: ...38 38...

Page 42: ...39 39...

Page 43: ...40 40 Electrical Cabinet Layout...

Page 44: ...41 41 CUTTERHEAD PARTS DIAGRAM...

Page 46: ...43 43 TABLE PARTS DIAGRAM...

Page 48: ...45 45 TABLE ROLLER PARTS DIAGRAM...

Page 50: ...47 47 INFEED PARTS DIAGRAM...

Page 52: ...49 49 STAND PARTS DIAGRAM...

Page 54: ...51 51 NOTES...

Page 55: ...52 52 NOTES...