12

12

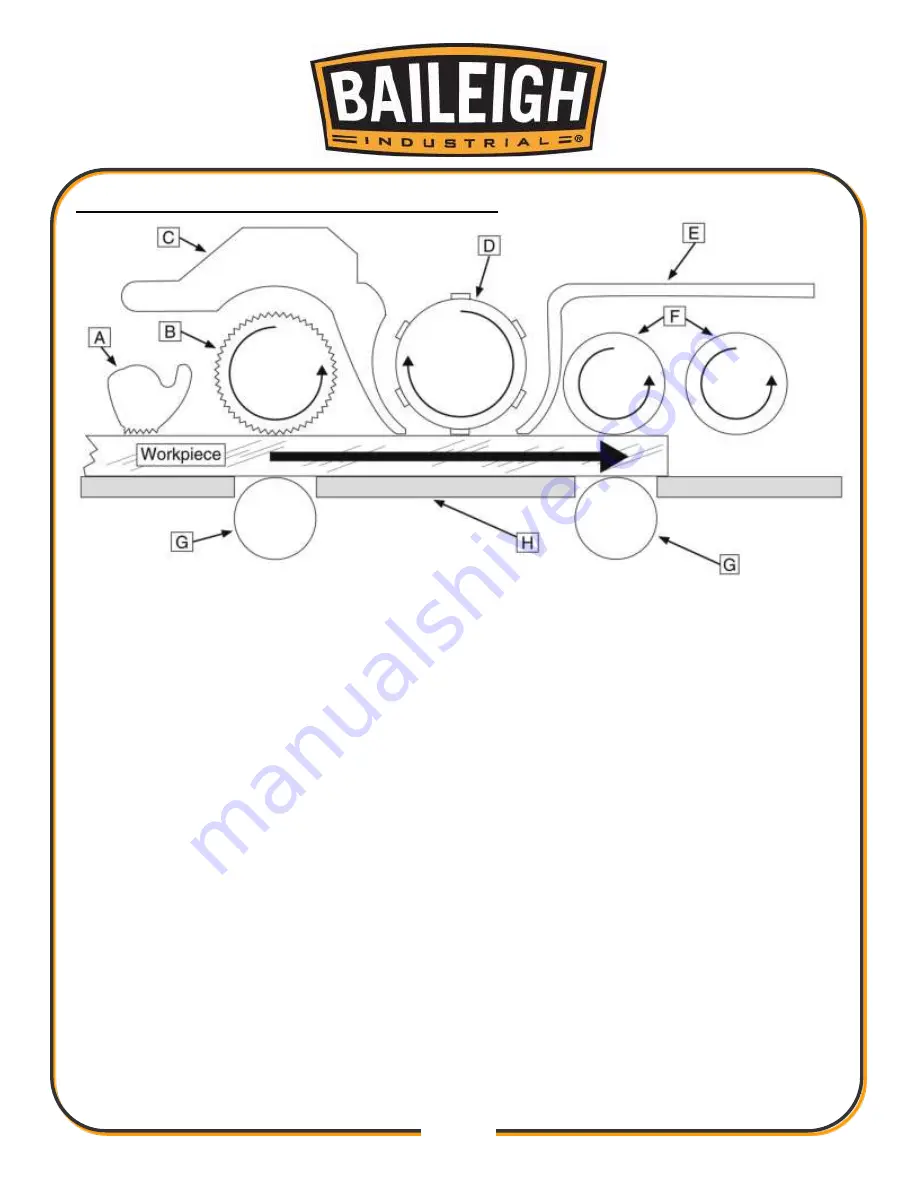

INTERNAL COMPONENT IDENTIFICATION

A.

Anti-Kickback Fingers:

Provide additional safety for the operator.

B.

Serrated Infeed Roller:

Pushes workpiece toward the cutterhead.

C.

Chipbreaker:

Breaks off chips created by the cutterhead to prevent tear out and diverts the

chips to the dust port.

D.

Spiral Cutterhead:

Holds the carbide inserts in a longitudinal spiral pattern that plane the

workpiece.

E.

Pressure Bar:

Stabilizes the workpiece as it leaves the cutterhead and assists in deflect- ing

wood particles toward the dust hood.

F.

Outfeed Rollers:

Pulls the workpiece toward the outfeed table.

G.

Table Roller:

Provide upward pressure on the workpiece enabling the feed rollers to pull

the workpiece along.

H.

Working Table:

Provides a smooth and level path for the workpiece as it moves through the

planer.

Fig. 3

Summary of Contents for IP-2511-HD

Page 39: ...36 36 ELECTRICAL SCHEMATIC...

Page 40: ...37 37...

Page 41: ...38 38...

Page 42: ...39 39...

Page 43: ...40 40 Electrical Cabinet Layout...

Page 44: ...41 41 CUTTERHEAD PARTS DIAGRAM...

Page 46: ...43 43 TABLE PARTS DIAGRAM...

Page 48: ...45 45 TABLE ROLLER PARTS DIAGRAM...

Page 50: ...47 47 INFEED PARTS DIAGRAM...

Page 52: ...49 49 STAND PARTS DIAGRAM...

Page 54: ...51 51 NOTES...

Page 55: ...52 52 NOTES...