37

37

Lathe Alignment

When the lathe is installed and ready for use, it is recommended to check the machine

alignment before beginning work. Alignment and leveling should be checked regularly to insure

continued accuracy.

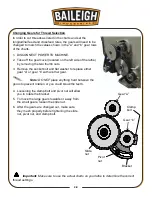

1. Start with a straight steel bar with a

diameter of 2.00” (approx. 50mm) x 10”

(254mm long).

2. Span it in the chuck without using the

tailstock.

3.

Cut off a chip over a length of 6”

(152mm).

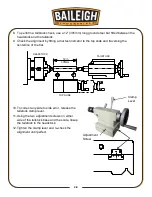

4. Measure and compare the diameters at

Point A and Point B. They should be the

same.

5. To correct a difference in readings,

loosen the four headstock hold-down

bolts shown, that hold the headstock to the bed.

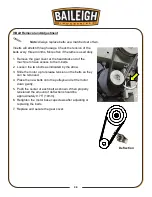

6. Adjust the headstock by backing off the jam nuts and re-

positioning the adjusting bolts.

7. Repeat steps 4 and 5 until the A and B dimensions are the

same.

Hold

down

A

B

6" (152mm)

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...