12

12

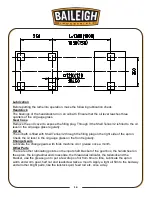

TRANSPORTING AND LIFTING

Follow these guidelines when lifting with crane or hoist:

•

Use lift equipment such as straps,

chains, capable of lifting 1.5 to 2 times

the weight of the machine.

•

Secure two lift straps around the lathe

base, staying behind the lead screw,

feed rod, and control rod. Be careful

not to damage any electrical cables or

coolant lines.

•

Take proper precautions for handling

and lifting by checking if the load is

properly balanced by lifting it an inch or

two.

•

Lift the machine, avoiding sudden accelerations or quick changes of direction.

•

Locate the machine where it is to be installed, and lower slowly until it touches the floor.

Follow these guidelines when lifting with truck or trolley:

•

The lift truck must be able to lift at least 1.5

– 2 times the machines gross weight.

•

Make sure the machine is balanced. While transporting, avoid rough or jerky motion, and

maintain a safe clearance zone around the transport area.

•

Use a fork lift with sufficient lifting capacity and forks that are long enough to reach the

complete width of the machine.

•

Remove the securing bolts that attach the machine to the pallet.

•

Approaching the machine from the side, lift the machine on the frame taking care that there

are no cables or pipes in the area of the forks.

•

Move the machine to the required position and lower gently to the floor.

•

Level the machine so that all the supporting feet are taking the weight of the machine and no

rocking is taking place.

CAUTION:

Lifting and carrying operations should be carried out by skilled

workers, such as a truck operator, crane operator, etc. If a crane is used to lift the

machine, attach the lifting chain carefully, making sure the machine is well balanced.

Choose a location that will keep the machine free from vibration and dust from other

machinery. Keep in mind that having a large clearance area around the machine is

important for safe and efficient working conditions.

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...