21

21

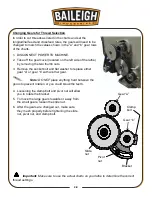

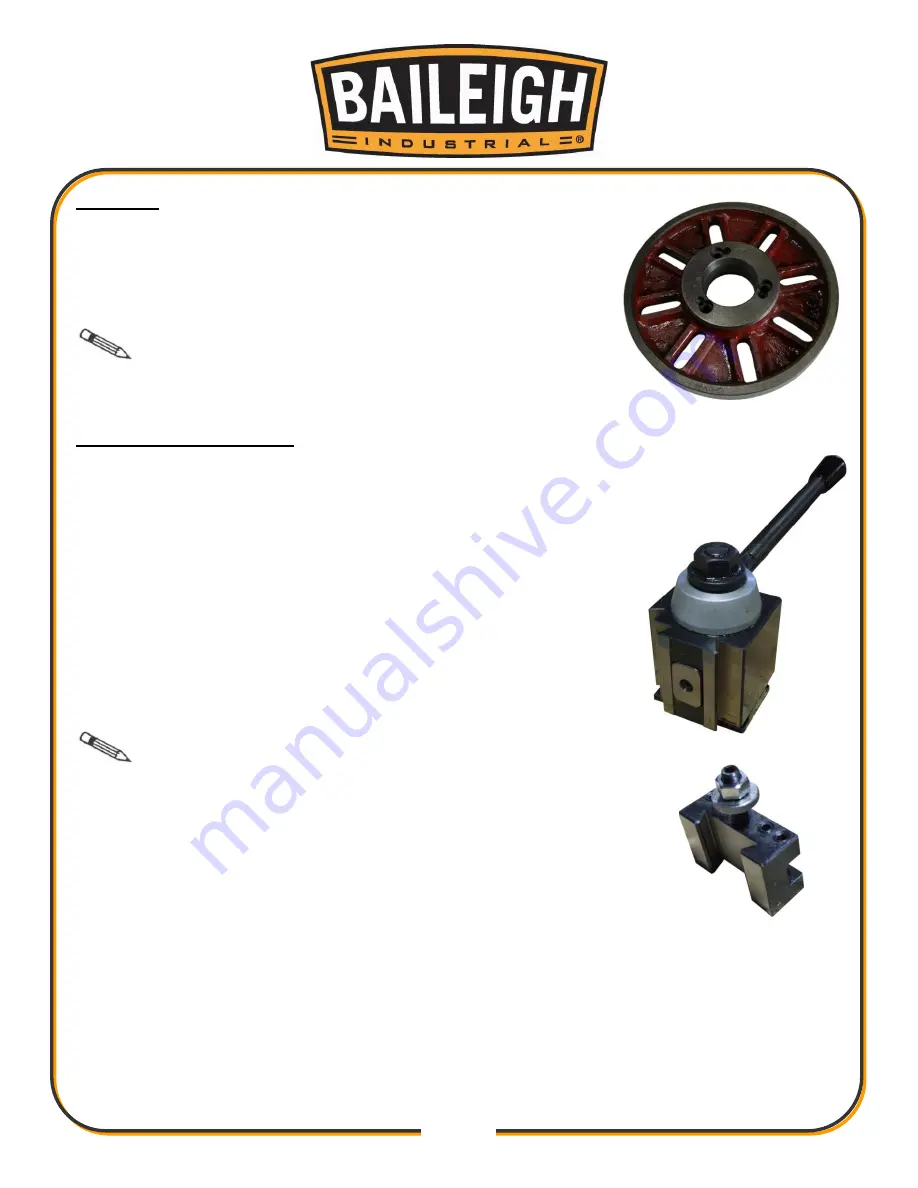

Faceplate

The faceplate is used for holding work that cannot be swung

between centers because of its shape and dimensions. The T-

slots and other openings on its surface provide convenient

locations for anchor bolts and clamps to secure the piece part. The

faceplate can be mounted to the spindle after removing the chuck.

Important: DO NOT exceed speeds greater than

770 rev./min. for a 10” faceplate.

Quick Change Tool Posts

This lathe comes with a quick-change tool post Model 250-200

(Phase II style) and four tool holders. These tool holders will all hold

up to a 5/8” square tool. Included are (3) Model 250-201 holders and

(1) Model 250-202 holder with a V-groove in the bottom of the holder

so it can also accommodate a boring bar.

The 250-200 tool post is the same as a

“BXA” style. The 250-201 tool

holder is a BXA-1 and the 250-202 tool holder is a BXA-2.

There are other tool holders and tool posts available. In the (Phase II

style) there are models 250-100, 250-200 and 250-300. The 100,

200, and 300 designate the size of the tool post and holders. The

corresponding numbers for these are AXA, BXA, and CXA. The 100

or AXA being for 1/2″ (12mm) square tooling, 200 or BXA for 5/8″

(16mm)

, and 300 or CXA for 3/4″ (19mm).

Note: If you have a 200-series tool post, only 200 or

BXA series tool holders will fit it, and to use other tool holders, a different

tool post must be purchased.

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...