22

22

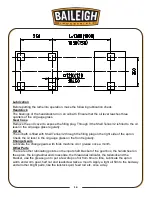

LATHE SETUP

Lubrication

This lathe comes pre-lubricated from the factory. It is still recommended to review the lubrication

procedure located in the Maintenance section of this manual. This will help you to become

familiar with the locations of lubrication fittings and areas where lubrication is required.

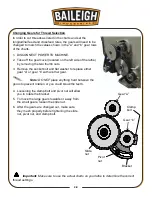

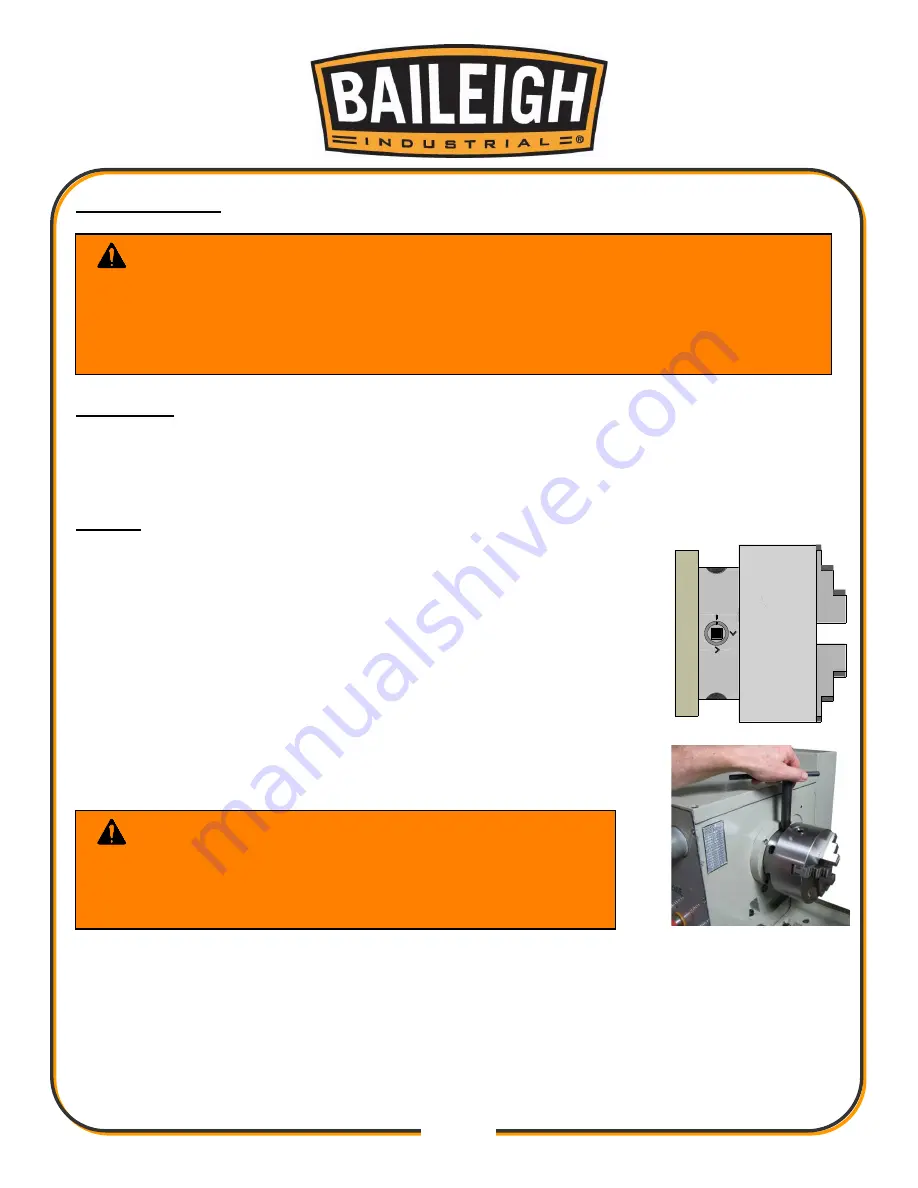

Chucks

This

metal lathe has a 6” (160mm) 3-jaw chuck already installed. This is

a scroll- type chuck which means that all three jaws close together and

are self-

centering. Also included is an 8” (200mm) 4-jaw chuck. The

four jaws move independently of each other and are used for holding

odd shaped pieces or where it is necessary to have zero tolerance.

Both the 3-jaw chuck and the 4-jaw chuck have Camlock mounting.

Note that there are lines stamped on the cam and on the chuck.

These indicate whether the cam is in a locked position or an unlocked

position where the chuck can be removed. A chuck key is used to turn

the locking cams as shown.

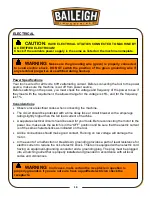

WARNING:

DO NOT start the lathe until all machine assembly has been

completed and you have been properly trained and understand all control functions.

When performing machine assembly make sure to follow proper lockout / tagout

procedures. Failure to comply could result in accidental starting of the lathe resulting

in SERIOUS OPERATOR INJURY OR DEATH.

WARNING:

NEVER leave a chuck key in the

chuck if the machine is not in use. If the lathe is accidentally

started with the key in place, it can become a projectile and

cause serious INJURY OR DEATH.

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...