23

23

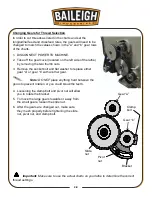

Chuck Removal

1. Lay a piece of plywood on the lathe bed directly beneath the

chuck. This will help protect the ways if the chuck should fall.

2. Turn the first cam counterclockwise (ccw) using the chuck key

until the line on the cam is aligned with the line on the spindle

housing as shown.

3. Rotate the spindle housing to access the remaining cams and

turn each one counterclockwise (ccw) until the marks are

aligned. Make sure to support the chuck with one hand as you

turn the last cam. You should now be able to remove the

chuck.

4. If the chuck is still tight on the spindle, tap the back of the chuck with a wooden or rubber

mallet while supporting the bottom of the chuck with your other hand. If needed, rotate the

chuck a bit, and tap again. Make sure all the marks on the cams and spindle are properly

aligned.

Chuck Installation

1. Lay a piece of plywood on the lathe bed directly beneath the spindle housing. This will help

protect the ways if the chuck should fall.

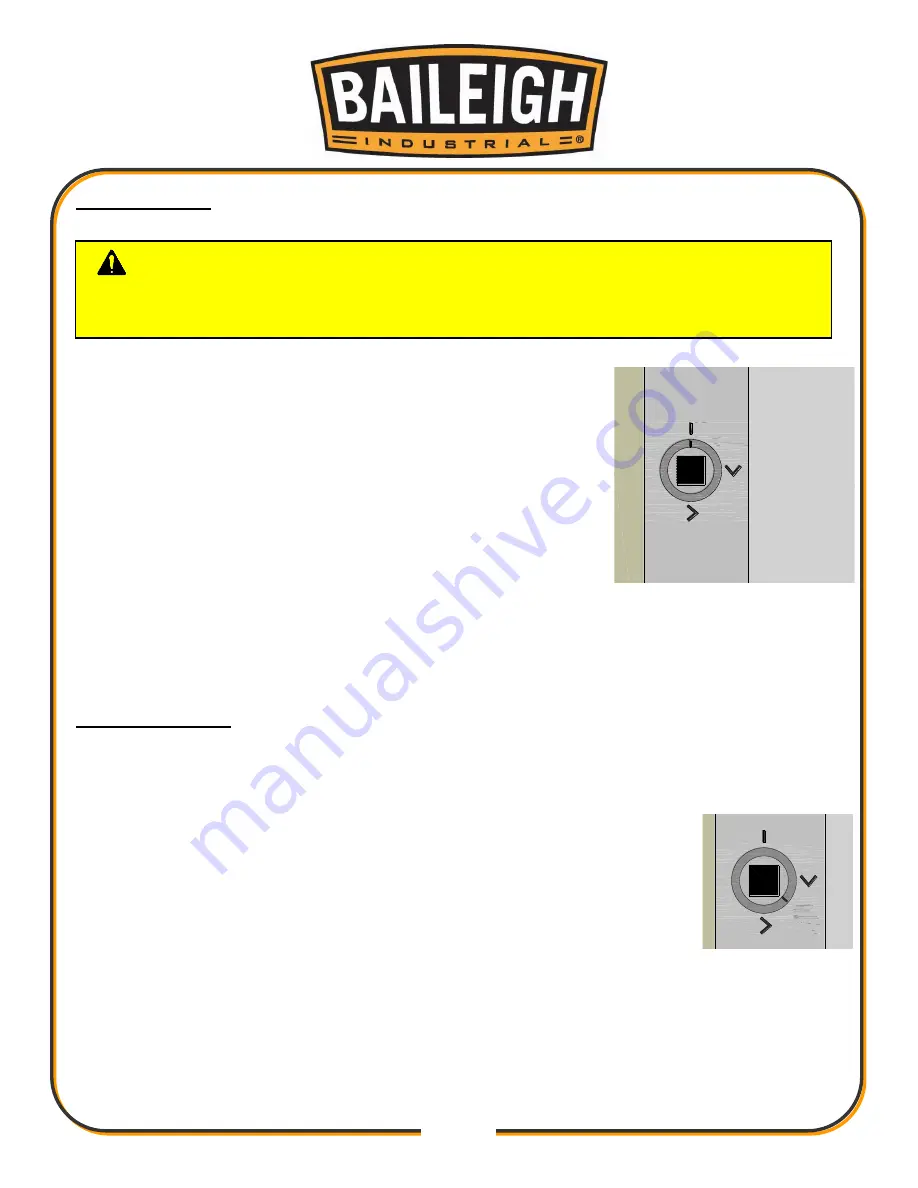

2. Lift the chuck up to the spindle and insert the camlock pins into the face

of the spindle.

3. While supporting the weight of the chuck, use the chuck key to turn one

of the cams until the cam line is between the two “V” marks on the

spindle as shown.

4. Rotate the spindle and repeat step 3 for the rest of the cams.

5. Starting with the first cam, snug up the cams.

6. Finally, recheck and fully tighten all of the cams.

CAUTION:

The Chuck is heavy. Use caution lifting the chuck during

removal and installation. If the chuck slips and falls, it can trap and crush hands and

fingers between the chuck and the plywood on the bed.

Spindle

Line

Cam Line

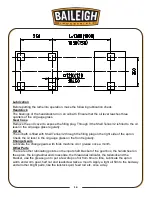

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...