31

31

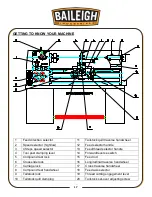

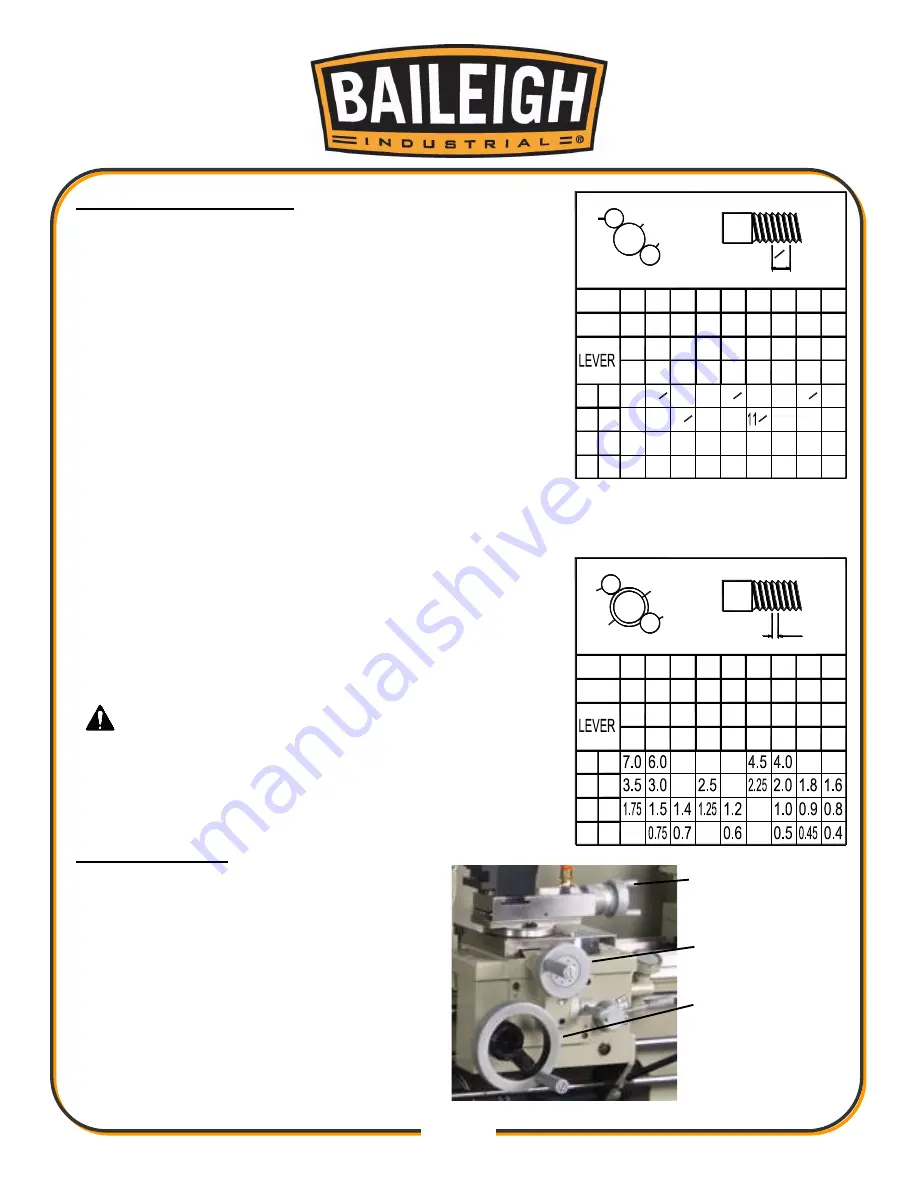

Thread Cutting Operation

In order to obtain the desired thread, change gears must be

installed correctly, using the values in the charts. Failure to

do so will result in incorrect threads.

1. First rotate the leadscrew by moving the feed/thread

selector (33) to any position and making sure the feed

selector knobs (2), (3), (4), & (5) are engaged.

2. Operate downward, the thread cutting engagement

lever (31) and it will engage with the leadscrew to obtain

the longitudinal travel of the carriage; namely the thread

cutting feed.

3. Make sure the feed axis selector is disengaged (at

neutral position) before operating the thread cutting

engagement lever (31) because there is an interlock

mechanism between the auto feeding and thread cutting

engagement.

Direction of the thread cutting can be chosen by turning the

feed direction selector (10) at the headstock. There are 31

thread pitches each in Imperial and Diametric as well as 26

metric thread pitches which can be obtained by turning the

feed selector handles (2), (3), (4), & (5).

Important: Make sure to use the actual charts on

your lathe to determine the correct thread settings.

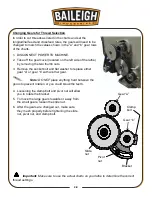

Carriage Controls

The carriage hand wheel when rotated,

allows the cutting tool to travel along the

length of the lathe bed. The cross slide hand

wheel when turned moves the cross slide in

and out perpendicular to the lathe bed. At the

top of the carriage is the compound slide

which allows linear movement of the cutting

tool at any preset angle.

Compound Slide

Hand wheel

Cross Slide

Hand wheel

Carriage

Hand wheel

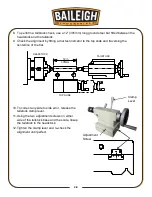

T

1"

a

b

120T

60

60

4

V

4

16

32

60 60 60 60 60 56 60 60

54 57 60 66 69 54 78 63

1 1 1 1 1 2 1 3

V V V V V V V V

4

1

2

5 5

6 6

7

1

2

1

2

8

9

1

2

1

2

9

10 11

12 13 14

18

36

19

38

20

40

22

44

23

46

24

48

26

52

28

56

a

b

A

B

A

B

D

D

C

C

mm

a

b

120T

56

60

4

R

60 60 30 60 60 30 60 56

63

1 3 4 1 3 1 3 3

R S T V R T V V

a

b

A

B

A

B

D

D

C

C

127T

60 60 60 60 60 60 60

5

Summary of Contents for PL-1340E-1.0

Page 48: ...45 45 ELECTRICAL DIAGRAM...