8

BA RoofOn V30 R16 12_2012 GB mit CE BAK.doc

4

3

4.1.

4.1.1.

4.1.2.

6.1.1.

6.1.2.

6.1.

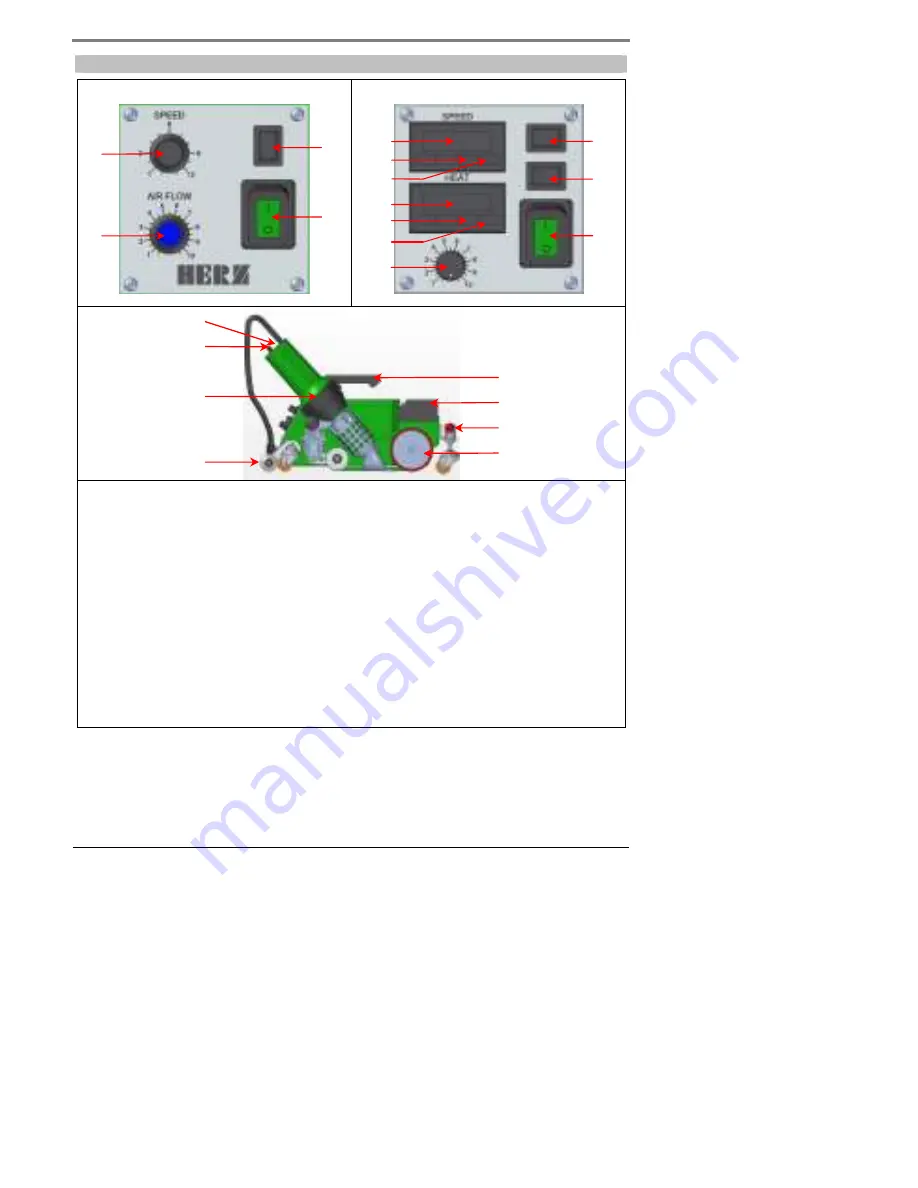

DEVICE DESCRIPTION

Standard operating panel

Digital operating panel

1

=

Main switch

ON / OFF

2

=

Manual drive

ON

(

only when button is pressed

)

3

=

Air flow adjustment (50 - 100 %)

4

=

Welding speed adjustment (0.6 - 12.5 m/min)

4.1.

=

Welding speed adjustment (0.6 - 12.5 m/min)

4.1.1.

=

Reduce speed

4.1.2.

=

Increase speed

5

=

Heating

ON / OFF

6

=

Welding temperature adjustment

6.1

=

Welding temperature adjustment

6.1.1

=

Reduce temperature

6.1.2

=

Increase temperature

7

=

Hot air system

8

=

Guide roller

9

=

Carrying handle

10

=

Weight (optional additional weight)

11

=

Lifting device

12

=

Pressure roller

6

7

8

9

10

11

12

5

2

1

3

2

5

1