Consolidated 2900-40 Series POSRV Instruction Manual

| 51

© 2020 Baker Hughes Company. All rights reserved.

XX. Setting and Testing (Cont.)

C. With Sensing Ring Option

Remote sensing is the standard pressure connection to

the pilot valve used on the 2900-40 Pilot Operated Safety

Relief Valve. However with the Sensing Ring Option, the

pilot valve pressure can be picked up just before the inlet

of the main valve.

The gaskets which are supplied by the customer are to be

inserted between the Valve Nozzle and the Sensing Ring

and between the Sensing Ring and the test system flange.

D. Functional Testing

ATTENTION!

!

Filter in sensing tube to be removed if the following filter

options are utilized.

1. Repeat set point verification tests 3 times.

a. Inlet pressure ramp guidelines.

(i) When set pressure is below or equal to 750 psig

(51.7 barg), the inlet pressure ramp should not

exceed 0.5 psig (0.03 barg), per second, when

test pressure is within 90% of set pressure.

(ii) When set pressure is above 750 psig (51.7

barg), the inlet pressure ramp should not

exceed 1.0 psig (0.07 barg) per second, when

test pressure is within 90% of set pressure.

c. Drop system to 90% of set pressure between

cycles.

d. The 3 tests should be within the tolerances listed in

Table 15.

e. If blowdown is being checked, the following

guidelines are to be followed.

Note: Blowdown can be set and checked on the main

valve only if the system can achieve 10% over

pressure.

(i) 39PV model (gas/steam): less than or equal to

5% or 3 psig (0.20 barg), whichever is greater.

(ii) 39PV model (liquid): between 7% and 4%. If set

pressure is less than 30 psig (2.1 barg), 3 psig

(0.20 barg), or less.

Note: Customer requirements may note a variation

to the standard blowdown. Customers request

takes priority.

CAUTION

Do not adjust blowdown, compression screw, or adjuster

while pilot is pressurized.

f. If adjustments are necessary, adjust Compression

Screw or Adjuster and retighten corresponding lock

nut. Starting position of adjuster shall be 8 turns.

Retest beginning at step 9.

2. Main valve equipped with metal seats and steam as

the test media.

a. Leak tightness shall be checked visually using

a black background. There shall be no visual or

audible leakage after the interior or the valve is

allowed to dry after popping. The leak test pressure

shall be when pressure is held at 4% below valve

set pressure or 2 psig (0.14 barg), whichever is

greater.

b. Increase pressure from 90% of set pressure to

4% below set pressure or 2 psig (0.14 barg),

whichever is greater, and check all ports and

connections for leakage on Pilot and Main Valve.

c. Repair of valves which show leaks in backpressure

testing may be attempted by tightening the joint

involved to normal tightness, while the valve is in

the testing area. The valve is to be examined for

cause of failure, the cause corrected, and the test

repeated.

d. To isolate leakage that may be coming from the

pilot, disconnect the pilot vent line (if applicable)

from the main base outlet and plug the main valve

outlet connection. If wet paper still bulges, then

leakage is occurring from main valve.

e. Leakage from main valve can come from either

the main valve seat, nozzle seal or dome seal. To

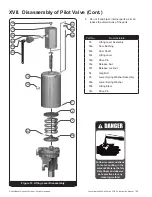

Figure 39: with Optional Line Filter