60 |

Baker Hughes

© 2020 Baker Hughes Company. All rights reserved.

XXII. 2900-40 Series POSRV Options (Cont.)

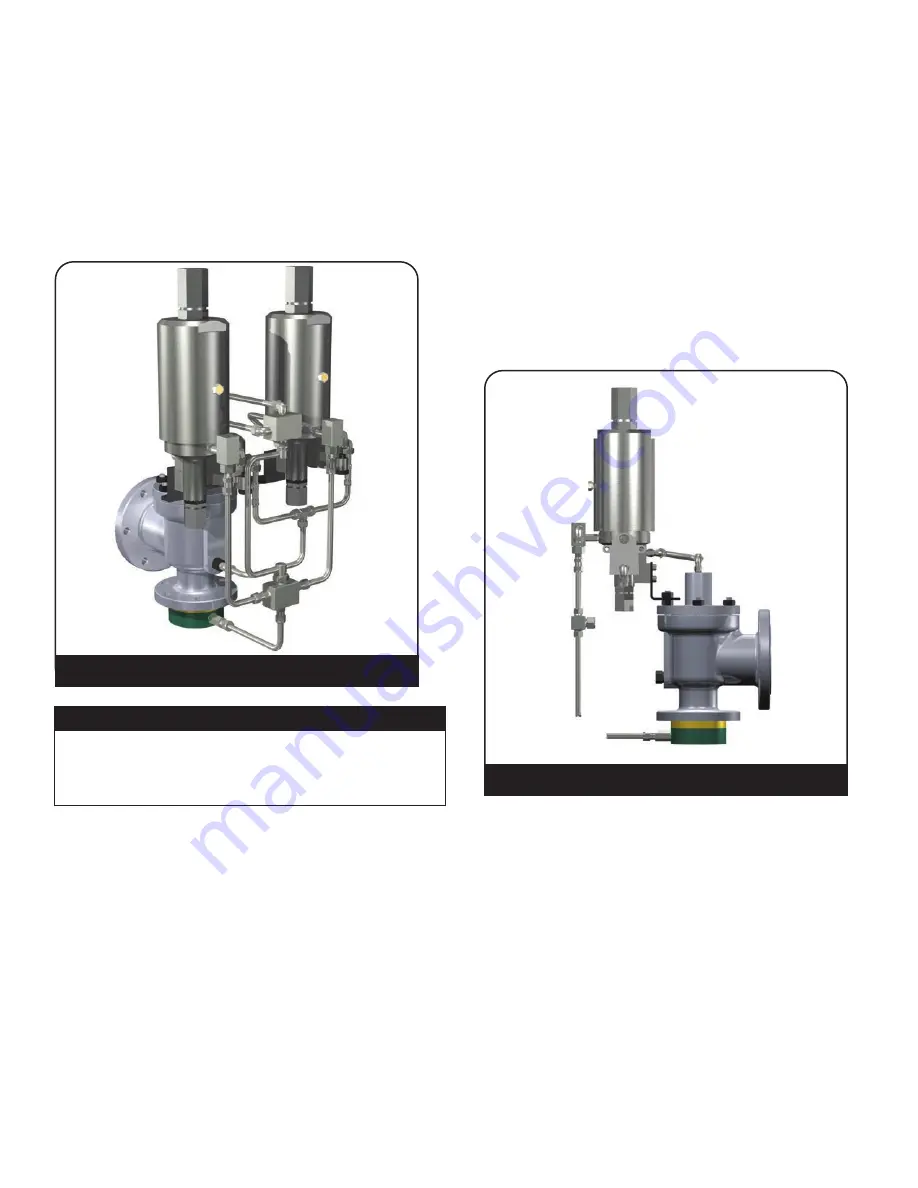

B. Dual Pilots

A dual pilot arrangement (Figure 46) is available for

applications in which the pilot valve soft goods require

monitoring and/or maintenance more often than the main

valve. In this installation, the pilot valves may be alternated

for maintenance, without bringing the system down.

ATTENTION!

!

When servicing dual pilots, procedures need to be in

place to perform a tag out / lock out of pilots under

pressure if they are in service.

C. Field Test Connection

A field test connection is standard on all pilot valve types.

This allows the stroking of the valve with an auxiliary

media, e.g. air or nitrogen. An internal check valve is

present in the field test connection isolating the inlet

media from the test media and at the same time, allowing

the valve to open normally in the event of a system over

pressurization during a field test. The test port connection

is a .375” (9.53 mm) tube fitting equipped with a bug

screen.

For all applications on air, water over 140°F (60 °C), or

steam service, ASME Section VIII - Division 1 requires

each pressure relief valve to have a lifting device such as a

field test connection or a means of connecting or applying

pressure to the pilot to verify that the moving parts

essential to good operation are free to move. (Reference

UG 136(a)(3)). The lifting lever or field test connection

may be omitted under Code Case 2203. All orders for

pressure relief valves without levers or field test connection

for steam, air and water over 140°F (60°C) must state

specifically that the valves are being purchased per Code

Case 2203. The purchaser is responsible for obtaining

jurisdictional authorization for use of Code Case 2203.

D. Single, Dual and High Capacity

Filters (Optional)

Filter options are available for dirty applications. These

filters are installed in the pilot inlet sensing line. For the

39PV, an optional sensing line filter is available (Figure

46). This filter has a 316 stainless steel body, Teflon

®

seals, and a 40-50 micron stainless steel filter element.

Other high capacity filter options (Figure 48) include:

1. A carbon steel cadmium coated filter body with a 35

micron stainless steel element; and

2. An entirely stainless steel filter arrangement. These

filters may be equipped with a manually operated

needle valve which allows for purging the filtered

material while the valve is in operation. All filter

elements are stainless steel, and all filters, including

carbon steel, conform to NACE Standard MR0103

and MR0175. A dual filter arrangement (Figure 49)

Figure 47: Sensing Line Filter

Figure 46: Dual Pilots