Masoneilan SVI II AP Digital Positioner Quick Start Guide

=

|

103

© 2018 Baker Hughes, a GE company, LLC. All rights reserved.

This discussion explains how to determine compliance voltage for an SVI positioner. It applies to

the SVI II AP, SVI II ESD, SVI II APN and SVi1000.

A definition of compliance voltage is: The voltage that must be available at the control system

output in order to drive the control current through the SVI II AP and all the resistive devices in

series with it.

Measuring the voltage across the SVI II AP terminals doesn't give the true available system com-

pliance voltage as the positioner self-regulates voltage as current flows through it. Additionally,

it also doesn't confirm what system voltage is available under load conditions.

Therefore, if com-

pliance testing needs to be done, it is best done before installation.

Use a 1K potentiometer as this is the maximum for most analog output cards and as at 20 mA

this equals 20 VDC, which is a sufficient maximum.

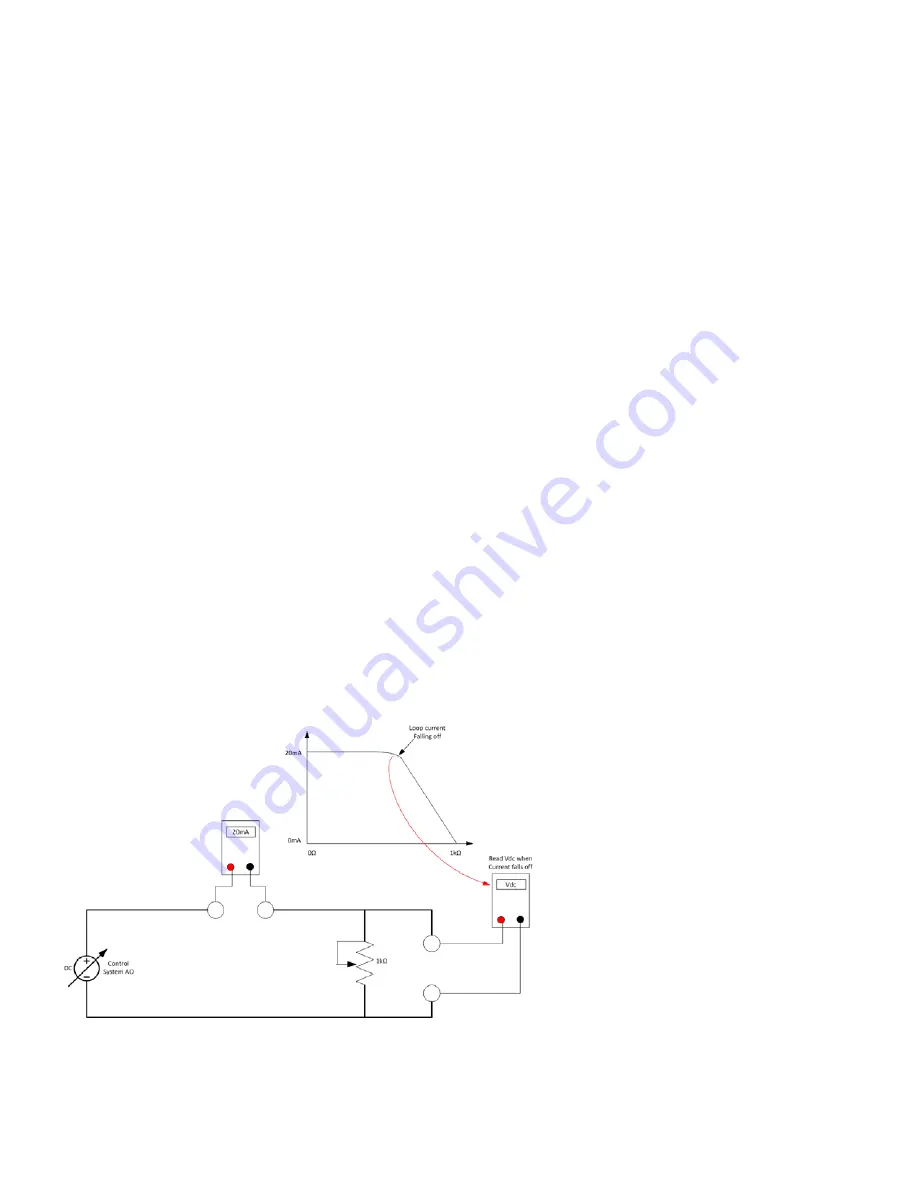

Compliance Test Set-Up

1. Configure a test set-up as in Figure 38.

Figure 38

Compliance Voltage Test Set-Up

2. Send 4 mA to the test set-up.

3. Increase the potentiometer value until the loop current reaches 3.95 mA.

4. Read the voltage across the potentiometer, which should be > 11 VDC. This is the

available system voltage at the minimum output.

D. Determining an SVI Positioner

Compliance Voltage in a Control System

Summary of Contents for Masoneilan SVI II AP

Page 6: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 68: ...This page intentionally left blank...

Page 90: ...2018 Baker Hughes a GE company LLC All rights reserved 90 BHGE Spare Parts...

Page 92: ...2018 Baker Hughes a GE company LLC All rights reserved 92 BHGE...

Page 94: ...This page intentionally left blank...

Page 102: ...This page intentionally left blank...

Page 105: ...This page intentionally left blank...

Page 106: ...This page intentionally left blank...

Page 107: ...This page intentionally left blank...