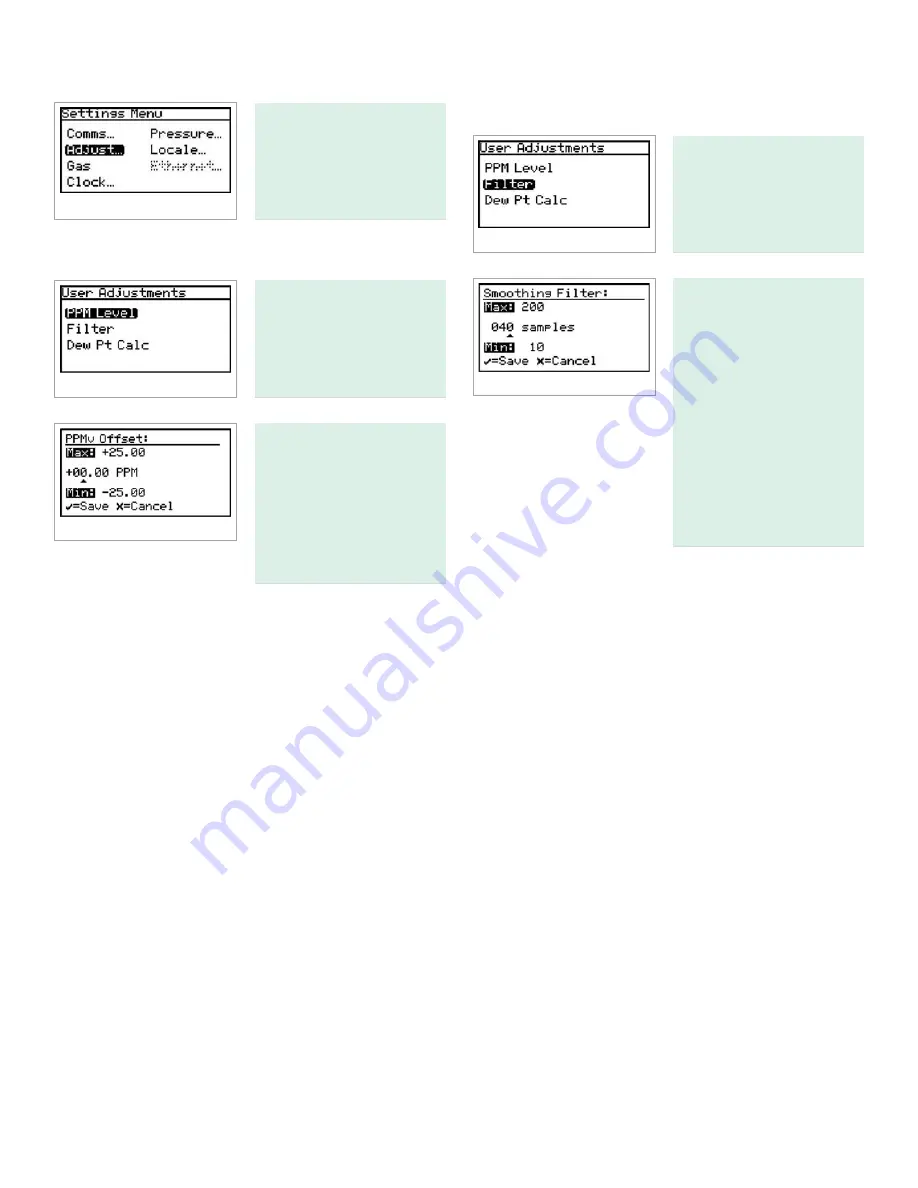

4.2 Adjust offset values

To adjust offset values,

from the settings menu

select adjust... and press

enter. The following screen

appears.

4.2.1 Adjusting the PPMv offset

To adjust the PPMv offset,

select PPM level and press

enter. The following screen

appears.

Use the left and right

arrow keys to select each

digit to be changed. Use

the up and down arrow

keys to change the value.

When finished, press enter.

The screen returns to the

user adjustments menu.

4.2.2 Adjusting the smoothing filter

To adjust the smoothing

filter, from the user

adjustments menu select

filter and press enter. The

following screen appears.

The smoothing filter setting

is used to change the

system responsiveness.

It is a moving average filter

to smooth the moisture

readings. 1 sample = 1

scan. The minimum setting

is 10 samples, or ~ 0.6

seconds. The maximum

setting is 500 samples, or

~ 31 seconds. The default

value of 40 samples, as

set at the factory, is ~2.5

seconds.

Use the left and right arrow keys to select each digit to be

changed. Use the up and down arrow keys to change the

value. When finished, press enter. The screen returns to the

user adjustments menu.

37

Summary of Contents for Panametrics Aurora H2O

Page 2: ...ii...

Page 4: ...no content intended for this page proceed to next page iv...

Page 20: ...no content intended for this page 10...

Page 32: ...no content intended for this page 22...

Page 71: ...Figure 74 Exporting a simplified image Figure 75 Selecting enhanced metafile 61...