Introduction

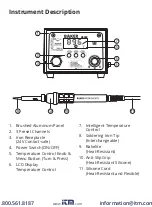

Thank you for purchasing your BAKER 3-Channel Soldering Station

with soldering iron and safety rest. Please read the following instructions

carefully before using your instrument. By following the steps outlined in

this manual your product will provide years of reliable service.

Product Quality

This product has been manufactured in an ISO9001 facility and has

been calibrated during the manufacturing process to meet the stated

product specifications.

Safety

Pre-operational Safety Checklist

• Examine the power cable and soldering station for damage.

• Do not operate this unit without a properly grounded, properly

polarized power cord. Permacolor mercury-free thermometer.

• Connecting the control unit incorrectly poses a risk of injury due to

electric shock and can damage the device.

• Ensure that the cord does not create a slip/trip hazard.

• Ensure the workspace is well ventilated to prevent fumes in the

breathing zone e.g. use in open area with cross ventilation or with

fume extraction system.

• Check condition of soldering tip. Replace if damaged.

• Ensure tip is "tinned" and free from waste build-up. Once the tip has

warmed-up, wipe on a damp sponge to clean it.

• Leave the soldering iron in the stand when warming up.

• Never leave a soldering iron unattended when turned on or still hot.

Unplug soldering iron when not in use.

www.

.com

information@itm.com

1.800.561.8187