Bugbox Plus

UM-17 R4.0

Page 44 of 47

Bugbox Plus User Manual

Gas consumption/ environmental control problems

Bugbox Plus is fitted with a gas demand indicator (item 7 in Figure 9). The indicator illuminates when

gas is injected into the workstation chamber. When the workstation is at rest, the gas demand

indicator should illuminate once every 20 minutes. At rest is defined as the workstation chamber is in

an anaerobic condition with no access to the interlock chamber, i.e. the glove ports are closed, the

interlock is closed and, if fitted, the SPES is closed. Figure 37 gives some common gas consumption

and environmental control problems and solutions;

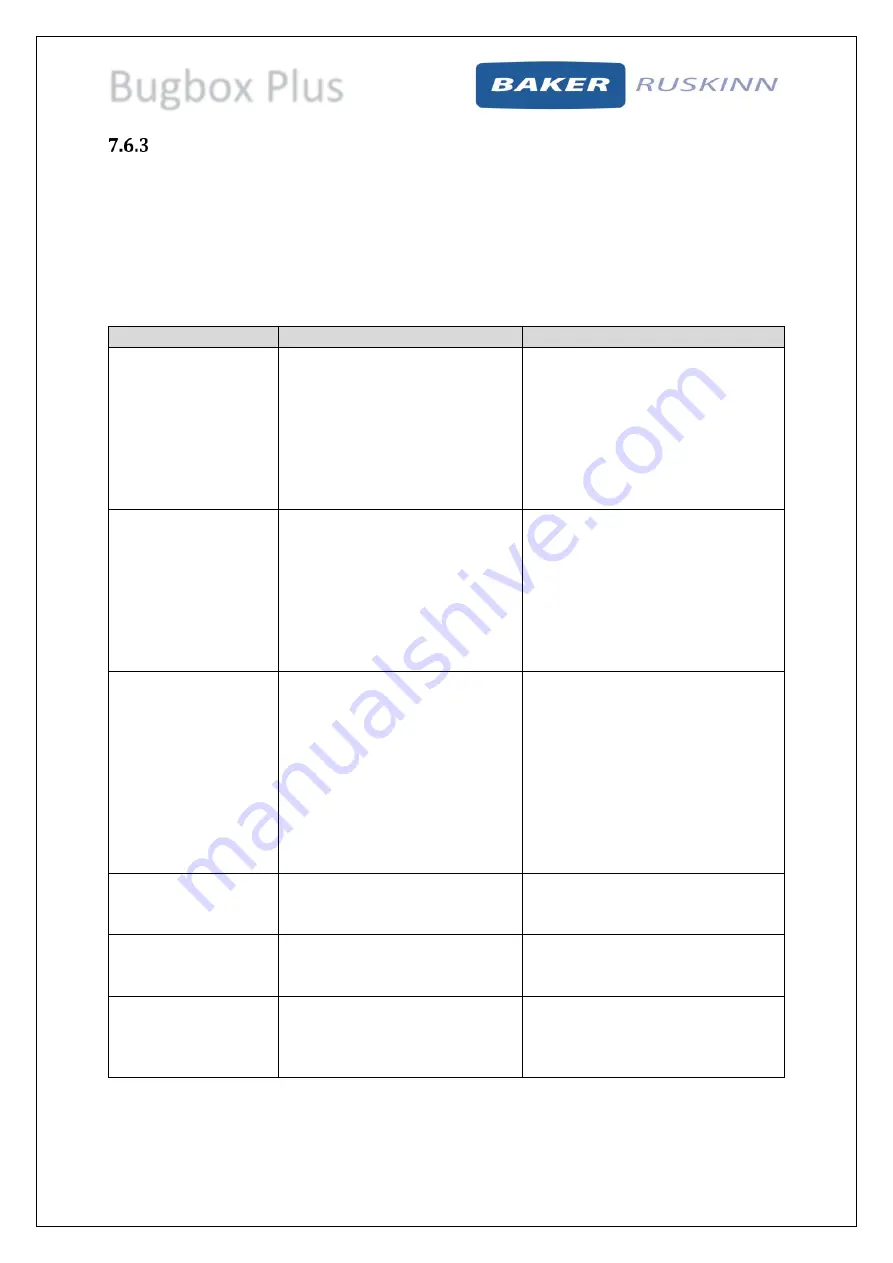

Figure 37: Gas consumption/ environmental control problems and solutions

Problem

Cause

Solution

The workstation is

failing to reach an

anaerobic condition.

The catalyst sachet has not been

installed.

The

catalyst

sachet

needs

replacing.

The anaerobic mixed gas supply

has run out.

Install a catalyst sachet. See section

7.2.3, for more details.

Replace the catalyst sachet. See

section 7.2.3, for more details.

Replace the anaerobic mixed gas

cylinder.

High gas consumption

when at rest.

The glove port cover has been left

open.

The SPES has been left open.

The interlock inner and outer

doors are both open.

Close the glove port cover.

Close the SPES. See section 6.5.1.1,

for more details.

Close the interlock inner and/ or

outer door.

High gas consumption

when in use.

The Ezee Sleeves have not been

correctly fitted.

The Ezee Sleeves are not sealing

around the users wrists.

Refit the Ezee Sleeves. See section

7.2.2, for more details.

Ensure that the Ezee Sleeves are the

correct size for the user. Ensure that

any clothing and/ or jewellery that

may foul the Ezee Sleeves is

removed/ rolled back. Ensure that

the Ezee Sleeves are pulled tight

around the user’s wrists.

The N

2

low indicator is

illuminated.

Low pressure in the nitrogen

supply caused by an empty

nitrogen cylinder.

Replace the nitrogen cylinder.

The

ANO

2

low

indicator

is

illuminated.

Low pressure in the anaerobic

mixed gas supply caused by an

empty nitrogen cylinder.

Replace the nitrogen cylinder.

An audible alarm can

be heard.

Low pressure in the gas supply,

caused by an empty gas cylinder.

Replace the empty gas cylinder. The

alarm can be muted by pressing the

gas alarm switch (item 3 in Figure 9).