Invivo

2

Plus

UM-14 Version R3.0

Page 49

Invivo

2

Plus User Manual

Replacing the mains fuses

7.4.6

To replace the mains fuses;

•

Remove the plug from the mains socket.

•

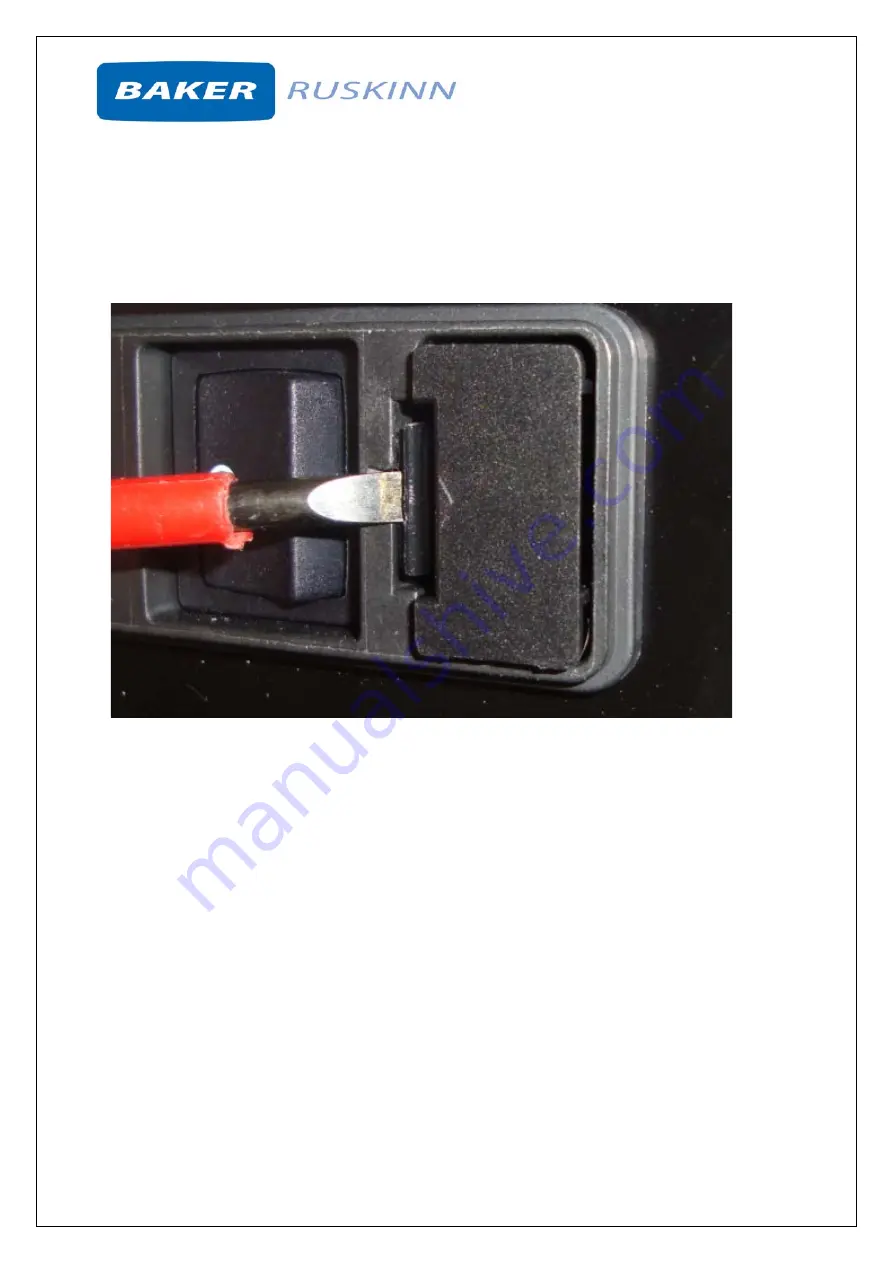

Remove the mains fuse drawer using a small flat bladed screwdriver. Figure 38 shows the

removal of the mains fuse holder;

Figure 38: mains fuse holder removal

•

Replace the mains fuses. The fuse ratings are;

•

240V 50Hz – F3.15A H250V

•

220V 60Hz – F5A H250V

•

110V 60Hz – F5A H250V

•

100V 50/60Hz – F5A H250V

Fuses should be fast blow, for example Cooper Bussmann S50 for more information, contact your

local distributor.

•

Replace the mains fuse holder. The fuse holder will click when it is fully inserted.

•

Replace the plug in the mains socket.

•

Switch the Invivo

2

Plus on.