INSTALLATION INSTRUCTIONS

SECTION ITEM

PAGE

1

Location

2

2

Electrical Connections

2

3

Requirements for Installation

3

4

Initial Start Up

3

OPERATING INSTRUCTIONS

SECTION ITEM

PAGE

1

General Baking

3

2

General Baking Tips

4

3

Special Features

4

4

Cleaning

5

5

Service and Trouble Shooting

5

6

Installation of Decks

6

WIRING DIAGRAMS & SCHEMATICS

ITEM

PAGE

P Series - 2 Chamber - 1 Ph, 2 W or 3 Ph, 3 W

(Wiring Diagram)

7

P Series - 2 Chamber - 3 Ph, 4 W - Star

(Wiring Diagram)

8

P Series - 1 Chamber - 3 Ph, 4 W - Star

(Wiring Diagram)

9

P Series - 1 Chamber - 1 Ph, 2 W or 3 Ph, 3 W

(Wiring Diagram)

10

P Series Counter Top Ovens - 2 Chamber

(Schematic)

11

P Series Counter Top Ovens - 1 Chamber

(Schematic)

11

PX-14 & PX-16

(Wiring Diagram & Tables)

12

PARTS LISTS & WARRANTY

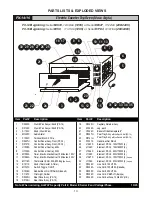

PX -14, PX-16 (New Style)

13

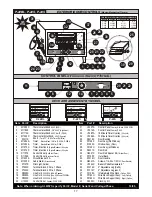

PX -14, PX-16 (Old Style)

14

P18-S & BK18

15-16

P-22BL, P-22S & P-24S

17-18

P-44S, P-44BL & P-48S

19-20

DP-2

21-22

Warranty

23

ITEM

PAGE

2

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or Parts, this information is required.

Model Number Serial Number Date Purchased

CONTENTS

INSTALLATION INSTRUCTIONS

Minimum Clearance for Installation

From combustible or non-combustible construction:

Right side, Left side and Back:

3” (76mm)

1. LOCATION

Due to the heat a counter-top oven may produce, it must be placed on a non-combustible surface.

Do not store combustible materials on top of any oven.

2. ELECTRICAL CONNECTIONS

Suitable means, which will disconnect all ungrounded conductors of the circuit simultaneously,

must be provided by the installer.

Make sure electrical supply corresponds with that specified on the rating plate located in the rear of

the oven.

When installed, the unit must be connected by an earthing cable to all other units within the

complete installation and thence to an independent earth connection.

Use copper conductors only, rated at 90° C.

If a line cord is used for the installation of the unit in Europe, it should be a minimum of H07RN-F type

conforming to EN60 335-1 and/or local codes.