HEAVY DUTY HOT PLATE OPERATION MANUAL

7

• Instructions are for conversion from Natural Gas to

Propane (L.P.) on all models BPHHPi and BPHHPSi.

• The conversion should be done before connecting

the unit to the gas supply.

• Units are shipped from the factory equipped for use

on natural gas. Orifices necessary for L.P. (propane)

are provided in a bag tied to the valve on the front

panel.

1. Remove the knobs and front panel.

2. Remove the orifice fittings from the valve. Change

the orifices to the size recommended for propane

(L.P.).

3. Replace the orifice fittings into the valve.

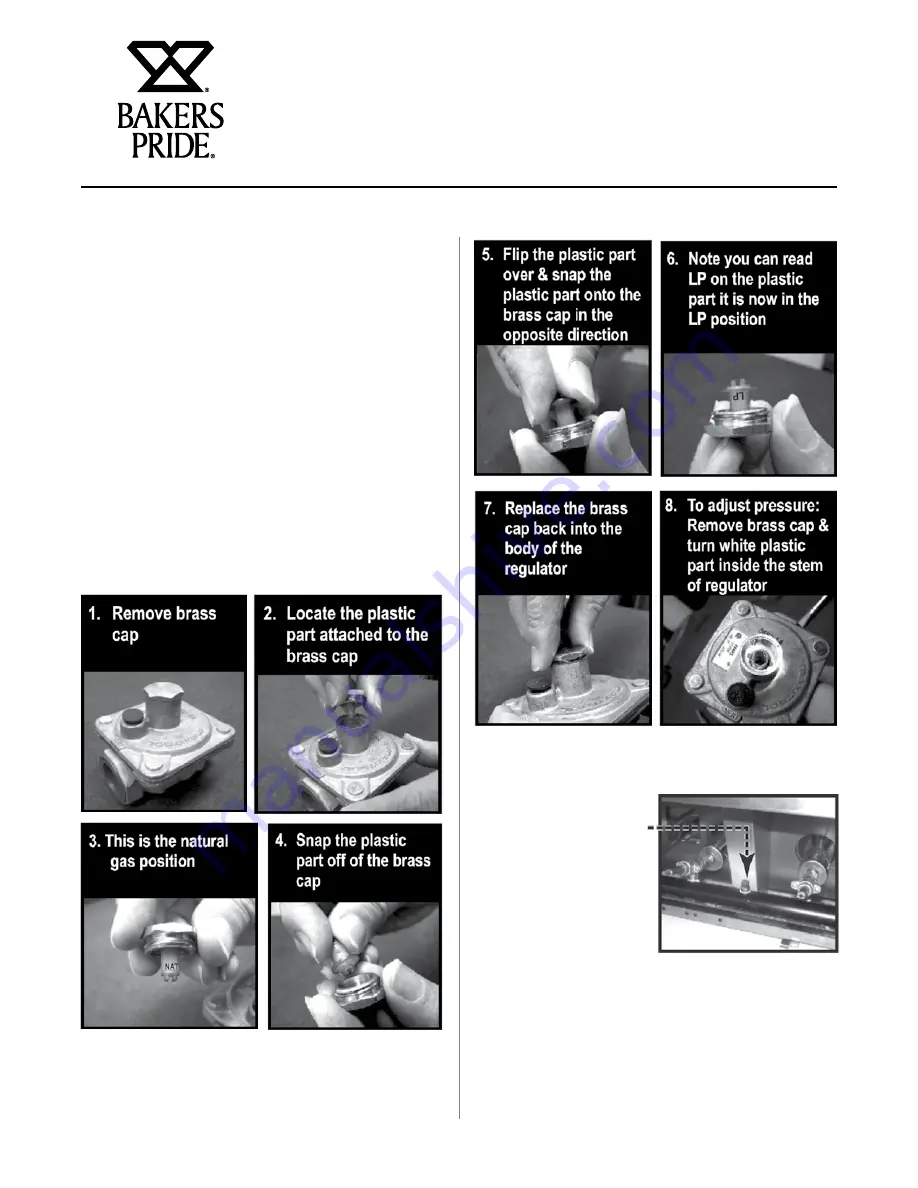

• To change the regulator:

CONVERSION

• Connect the regulator to the unit, connect gas and

check for leaks.

• Check the system

pressure. With the

front panel removed,

remove the plug from

the manifold.

• Place a fitting in the

plug opening and

connect a manometer.

• For Natural gas

the pressure in the manifold should be 5” water

column or 12.4 millibar. For L.P. the pressure in

the manifold should be 10” water column or 24.9

millibar.

• To adjust the pressure remove the brass cap and

turn the white plastic part inside the stem of the

regulator. See picture regulator 8.

Summary of Contents for BPHHP-212i

Page 13: ...11 NOTES...