9

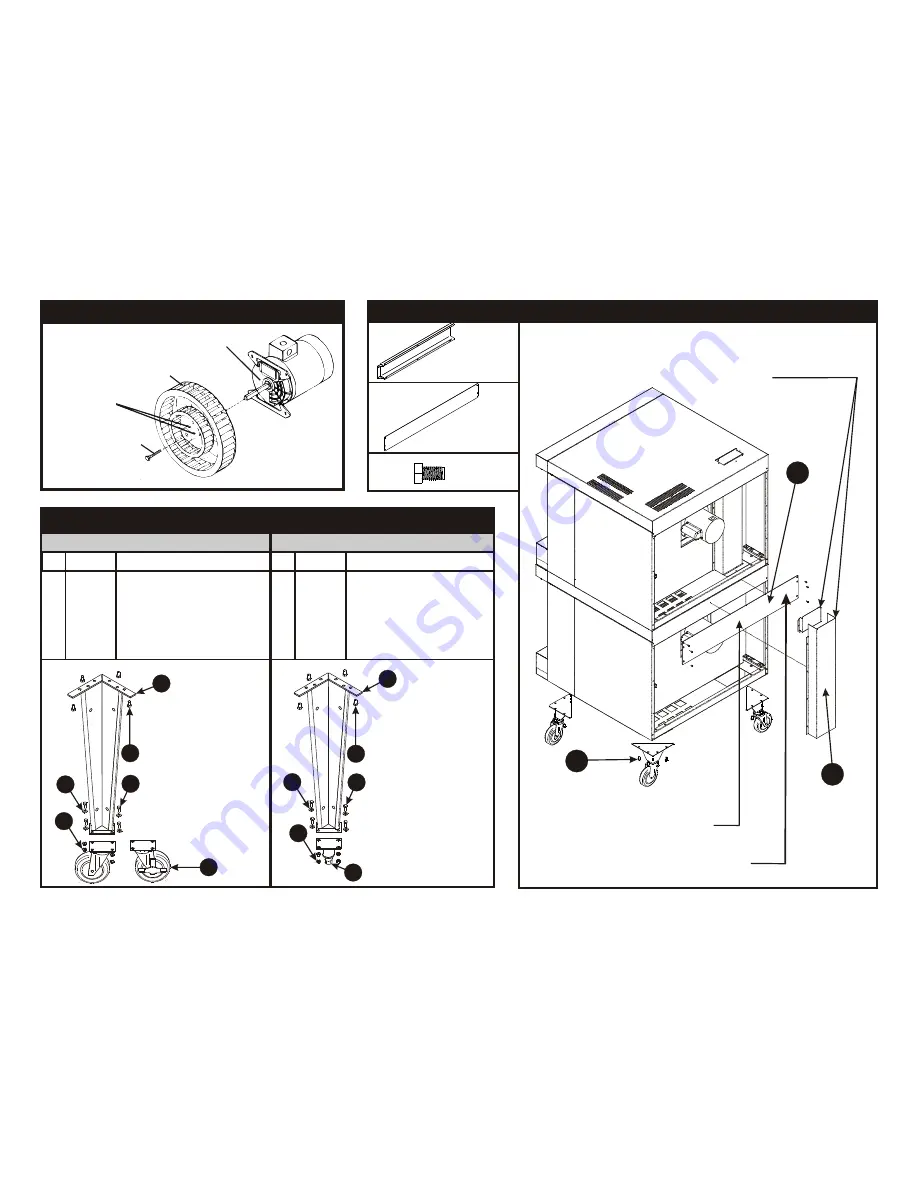

Motor

Blower

Wheel

Set Screw (2)

Wheel Puller

Bolt 3/8” Hex

Item 1

Item 2

Item 3

E3770A

E3771A

3/8”-16 Bolt

1. Attach two item 2 to two

item 1 using item 3, 4 and 5.

2. Attach two item 7 to two

item 1 using item 3, 4 and 5.

3. U s i n g p r o p e r l i f t i n g

equipment attach item 1 to

the corresponding hole

patterns located in the

bottom of the oven with

item 6.

1

21796810 Weldment, Oven Leg

2

8633102

Caster, 5” Swivel W/Top Plate

3

8227700

Hex Hd 5/16-18 X ¾ Bolt #5 Zn

4

8509300

Washer, Flat SAE, 5/16

5

8435000

Hex-nut 5/16-18

6

82447-00 Hex Hd. 3/8-16 X .750 #5

7

8633101

Caster, 5" Swivel W/Plate & Brake

With Plate Caster

LEG ASSEMBLY INSTRUCTIONS - MODEL:BCO-E & GDCO-E

1

21796810 Weldment, Oven Leg

2

8633515

Foot Insert, Adjustable

3

8227700

Hex Hd 5/16-18 X 3/4 Bolt #5 Zn

4

8509300

Washer, Flat, SAE, 5/16

5

8435000

Hex-Nut 5/16-18

6

82447-00

Hex Hd. 3/8-16 X .750 #5

1. Attach four item 2 to four

item 1 using item3, 4 & 5.

2. Using proper lifting

equipment attach i t e m 1

to the corresponding hole

patterns located i n t h e

bottom of the oven with

item 6.

Without Plate Caster

Item P/N Description

Item

P/N

Description

Figure 4

Figure 3

STACKING INSTRUCTIONS FOR: BCO-G & GDCO-G CONVECTION OVENS

CLEANING THE BLOWER WHEEL

Figure 2

Attach part # 21818062 with 6

each 8-32 stainless screws

Material: 14 ga201 Stainless

Remove the outer and inner flue from the

bottom oven before placing the top oven (to

prevent damaging the bottom oven’s flue). Re-

install after top oven is positioned.

2

1

3

22

1

77

6

44

3

55

4

66

5

33

2

22

1

77

6

44

3

55

4

66

5

88

7