INDEX

INSTALLATION INSTRUCTIONS

SECTION

ITEM

PAGE

1

Receiving

2

2

Location & Minimum Clearances

2

3A

Set-Up & Mounting for COC-E1

3

3B

Set-up & Mounting for CO11-E

3

4

Electrical Connections

4

5

Initial Start Up

5

6

System Check & Rotary Controls

5

7

Steam Injection (Optional)

6

OPERATING INSTRUCTIONS

SECTION

ITEM

PAGE

1

General Instructions

6

2

System Operation Sequence

6

1. Cook Only (Rotary Control)

6

2. Timed Cooking (Rotary Control)

6

3. Cook & Hold (Rotary Control)

6

4. Steam Injection [Optional] (Rotary Control)

7

5. Oven Cool Down (Rotary Control)

7

3

Cleaning

8

4

Servicing

9

5

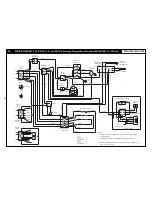

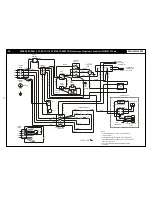

Wiring Diagrams

10

a. COC-E & CO11-E,

208 or 220-240V w/Invensys Temperature Controller

10

b. COC-E & CO11-E,

230-400V CE w/Invensys Temperature Controller

11

c. COC-E & CO11-E,

208 or 220-240V w/FAST Temperature Controller (G-6)

12

d. COC-E & CO11-E,

230-400V CE w/FAST Temperature Controller (E-6)

13

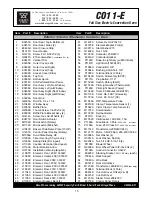

6

Parts Lists w/Exploded Views

14

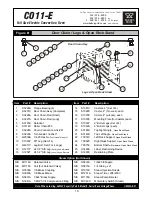

a. CO11-E

14

b. COC-E

17

7

Warranty

20

2

INSTALLATION INSTRUCTIONS

1. RECEIVING

Read the notice on the outside carton regarding damage in transit. “CONCEALED DAMAGE”,

damage discovered after opening the crate(s), must be reported immediately to the carrier. The carrier

will perform an inspection of the damage and furnish forms for the consignee's claim against the carrier.

Retain all packing material - including outer carton until the inspection has been completed. When the

oven arrives, it should consist of: A crate (or carton) containing your new oven, and a carton containing

four 30” legs with mounting hardware (for CO11-E1 oven only). A set of four 6” legs (for CO11-E2

stacked installations) and legs for COC-E are packed inside the oven.

2. LOCATION & MINIMUM CLEARANCES

a. Provision of adequate air supply to the oven for ventilation is essential. Minimum clearances must

be maintained at all times.