4.

MAINTENANCE:

(a)

SERVICE:

(b)

CAREAND CLEANING OF TOP GRATES:

(c)

GREASE COLLECTION:

(d)

CLEANING TOOLS:

Shut off the main gas supply before attempting any maintenance on the unit. If required, contact

your Dealer, the Factory, or a local Service Company to obtain qualified maintenance and repairs.

The top grates should be cleaned using a stiff wire brush. If this is done daily, the accumulation of

food and fat caught in the grates and work necessary to keep them clean will be reduced.

Periodically, they should be turned over and brushed and then put back. In the event that an extra

amount of fat is accumulated on the top, due to use of low heat, we recommend turning up the flame of

this section for about an hour, which will burn off much of the fat and residue and the brushing

operation will be easier. Under no circumstances should the grates be placed in a dishwasher. Soap,

water, or any detergents should never be used on the cast iron grates.

Your char-broiler is designed to bring grease into the front channel which in turn drains the grease into

the grease collection pan in the lower section of the broiler. The pan in the lower section should be

cleaned daily or more often if necessary. The channel should be cleaned periodically with a stiff brush

or scraper.

Several models of specially designed top grate brushes and grease drain scrapers are available from

Bakers Pride. Contact Bakers Pride for more information.

8

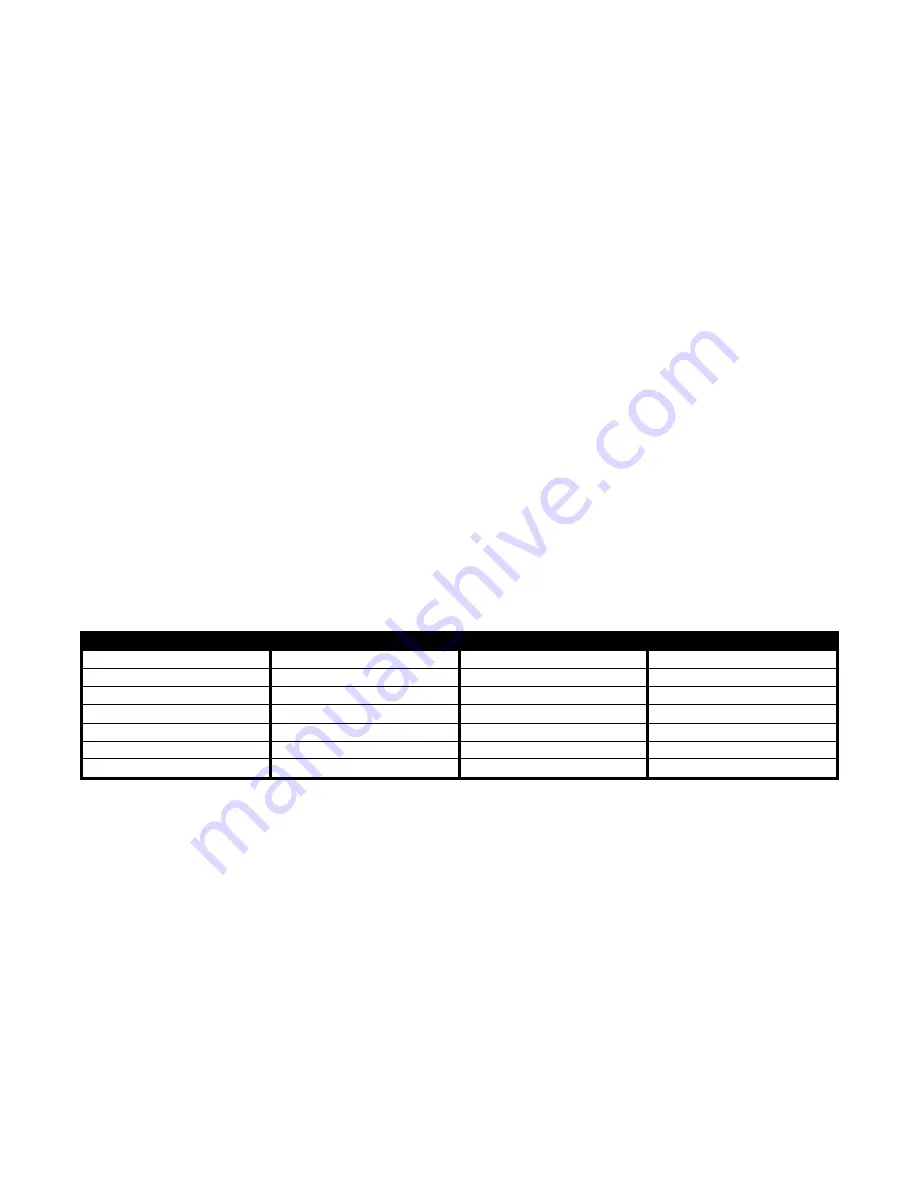

MODEL NUMBER

BROILING AREA

3 OZ. BURGERS

12 OZ. STEAKS

CH-4

XX-4

CH-6

XX-6

CH-8

XX-8

CH-10

XX-10

CH-12

CH-14

CH-16

21” x 24”

31 1/2” x 24

42” x 24”

52 1/2” x 24”

63” x 24”

73 1/2” x 24”

84” x 24”

600

900

1200

1500

1800

2100

2400

120

180

240

300

360

420

480

Estimated Hourly Production

The table above gives estimated hourly production as a guide only.Actual production may vary depending on required

doneness, thickness and weight of product.

5. AVERAGE PRODUCTION GUIDE:

XX-12