Figure

“E”

V

H

S

eries

Ovens

O

nly

Figure

“C”

Blower

Motor

Cover

Assembly

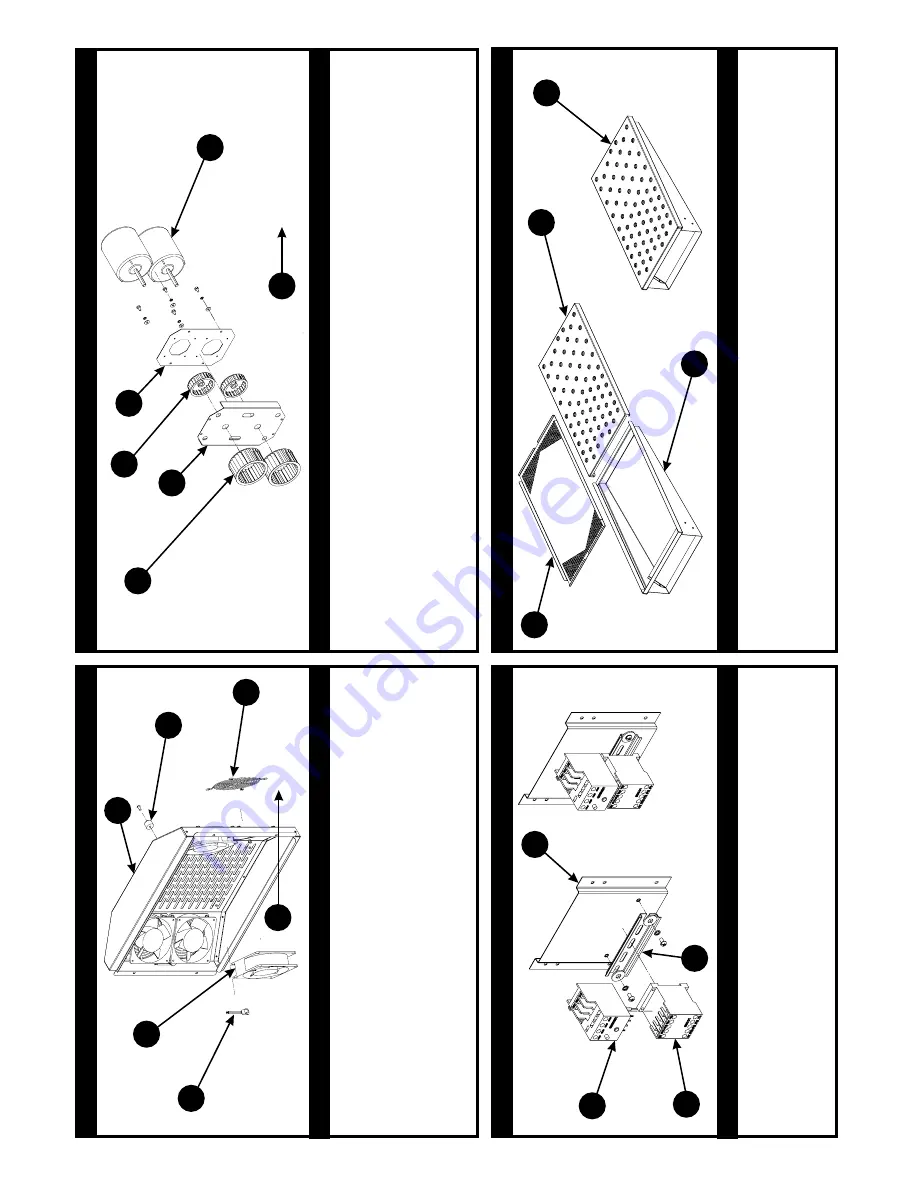

Figure

“F”

Plenum

“Finger”

Assembly

Figure

“D”

B

lower

Assembly

Item

P/N

Description

Quan

Item

P/N

Description

Quan

Item

P/N

Description

Quan

Item

P/N

Description

Quan

1

2

3

4

5

6

1

2

3

4

5

6

All

Component

s

Shown

All

Component

s

Shown

4

3

2

1

1

2

3

4

1

2 3 4 5 6

1

1 4 4 2 4

M1

193A

Q1504A P6471A

B6219U S1392A

B6323T

COOLING

FAN,

115V

FA

N

GUARD

FA

N

CORD

ASSY

REAR

BLOWER

MOT

OR

COVER

RUBBER

BUMPER

COMPLETE

REAR

BLOWER

MOT

OR

COVER

ASSY

(ITEMS

2-6

)

1 2 3 4 5 6

1 2 1 2 1 2

B6027K M1510A

B6031K S3260A

M1548U M1548A

MOT

OR

MOUNT

BRACKET

ASSY

MAIN

B

LOWER

WHEEL

MOT

OR

MOUNT

PLA

TE

HEA

T

S

LINGER

WHEEL

COMPLETE

BLOWER

MOT

OR

ASSY

(ITEMS

2-6

)

BLOWER

MOT

OR,

1/4

HP

,1

15/230

V,1P

H

1 2 3 4

1 1 1 1

M1385A M1386A

B6086U P1

150Z

CONT

ACT

OR,

15A,

3-POLE,

115V

OVERLOAD

RELA

Y

MOUNT

BRACKET

ASSY

DIN

RAIL

1 2 3 4

4 4 4 4

B6226K B6222U

B6221T B6225K

INNER

PERFORA

TED

PANEL

MAIN

BODY

PANEL

COMPLETE

P

LENUM

"FINGER"

ASSY

(ITEMS

2-4

)

OUTER

EXTRUDED-HOLE

PANEL

26