9

© 2010 Bakker Hydraulic Products B.V.

Nijverheidsweg 6

6662 NG Elst (Gld) The Netherlands

Tel : + 31 481 374757 Fax : + 31 481 375280

Site :

E-mail :

Reassembling the cylinder :

Assemble the cylinder parts in the reverse order to which you dismantled

them.

N.B.:

When mounting the head bush, you must use Loctite type 243 or a

comparable locking agent.

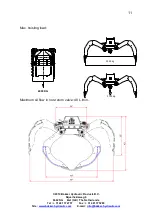

3. MAINTENANCE AND REPAIR

- Check the hoisting hook visually once a year, and test the hook once

every 4 years with an 6500 kg load divided into 4000 kg per hook.

- Test the non-return valve once a year to ensure that it is working

properly.

- Check pins and bushes every year for slack (maximum 0.8 mm).

- If the exchangeable blades are worn, they must be replaced by new

blades (maximum 25 mm per blade edge).

- Regularly grease the pivots (steady link, cylinder suspension and pins)

to prevent penetration of sand, dirt, etc.

- After 20 working hours, check all bolted connections and tighten if

necessary.

Caution!

With all maintenance activities on the grab bucket, the grab bucket must

be non-operational and stationed on the ground.

4. TROUBLESHOOTING

Problem :

Load is no longer held.

Possible causes :

- Non-return valve and/or seals

- Piston seals worn

-

External leakage’s to cylinder tube

Tips for tracing faults :

- The cylinder may not display any external leakage

’s. If it does,

check that the head bush is tight. If the head bush is loose,

the seals must be replaced.