11

© 2010 Bakker Hydraulic Products B.V.

Nijverheidsweg 6

6662 NG Elst (Gld) Holland

Tel : + 31 481 374757 Fax : + 31 481 375280

Site :

E-mail :

7. Maintenance and repair

Clean the RotaQ regularly. Potential faults can be discovered sooner.

The RotaQ connection components will be under significant force when used and checking loose

bolts and oil spills of the RotaQ coupling unit (see p. 4) and the tool plates must take place at least

every month.

All inspection and maintenance must be performed on a disengaged unit and depressurised system.

If the RotaQ exhibits any glitches when coupling or decoupling, then immediately

contact the helpdesk as mentioned in chapter 6

To keep the RotaQ in a good state of repair

•

Regular inspection and maintenance of the RotaQ - 100 coupling unit

(see p. 4) and the lower plates is required.

•

Maintenance and inspections can only be performed by sufficiently

technically qualified personnel.

•

Maximum contamination of the hydraulic oil is 10 µm.

•

Monthly visual inspection of the operation of all mechanical parts. In

case of any identified deviations, please contact your supplier/installer

before further use.

•

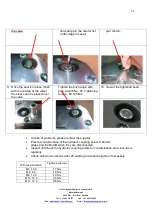

Monthly inspection of the state of the seals of the hydraulic lower plate.

It is possible that the seal in the hydraulic lower plate will start leaking

due to damage. In this case, you must replace the seal. A first spare set

of sealing rings will be provided with the RotaQ by default.

•

During the monthly inspection, check the RotaQ - 100 for damage to

the coupling unit (see p. 4), lower plates, other components that are part

of the RotaQ - 100 and weld it if possible.

•

Repair descriptions have not been included in the manual; for questions

you can always contact your supplier/installer.

•

Prevent decontamination of the hydraulic connection points of the

support plates and the RotaQ - 100 when decoupled.

•

Inspect and check the hydraulic connection points for decontamination

and dirt and clean them regularly.

•

Maximum contamination of the oil may be 10 µm.