1

●

Be sure your power voltage is same as the unit's supply voltage

before connect the power cord.

●

Be sure grounding the unit.

●

After use unit, please turn off unit and unplug.

●

Do not touch the metal parts near the tip while using.

●

Before replacing parts or storing the unit, turn the power off and allow

the unit cool down to room temperature.

●

Do not use the product near flammable items.

●

Do not modify the unit.

●

Use only genuine replacement parts.

●

Do not wet the unit or use the unit when your hands are wet.

●

The soldering process will produce smoke, so make sure the working

area is well ventilated.

CAUTION

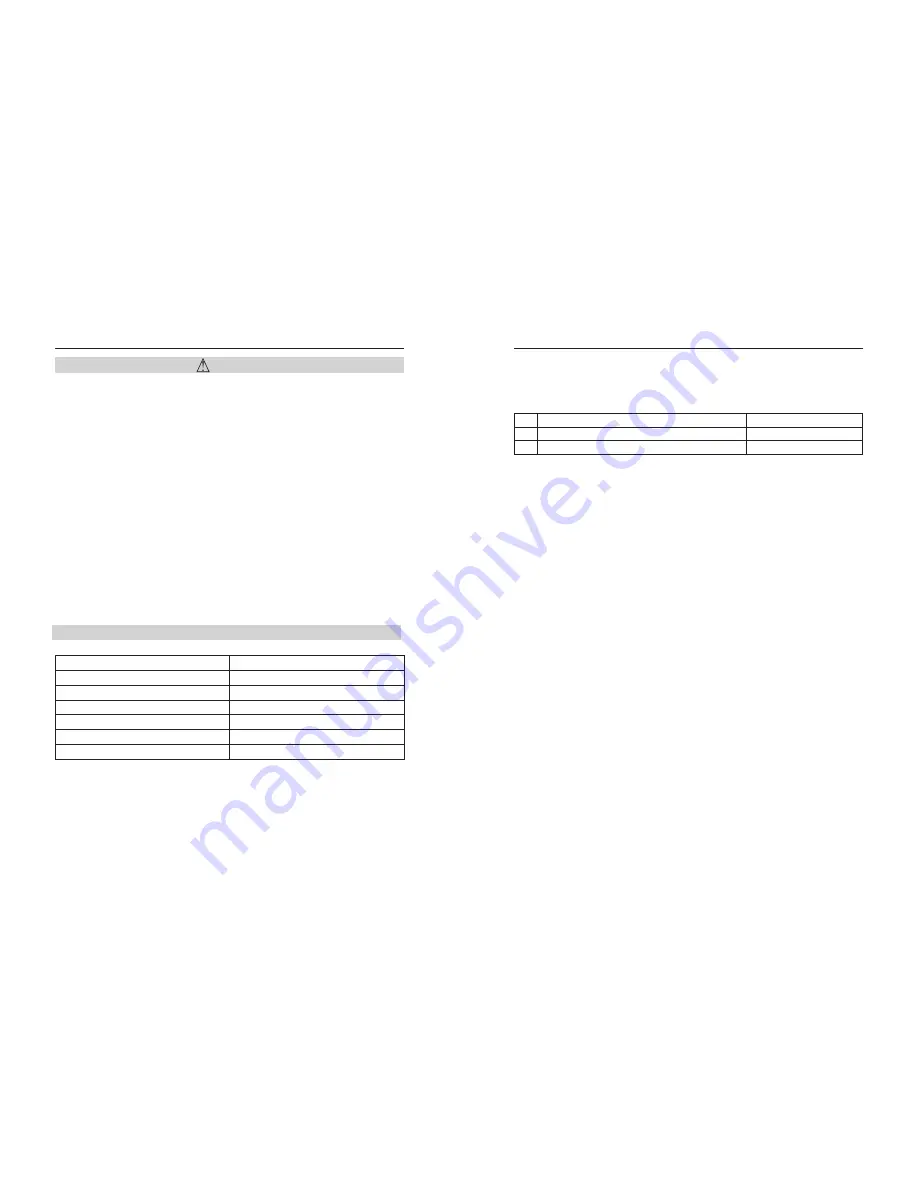

Packing List

1

1

1

1

1

1

Item

Quantity

Lead free soldering station

Iron

Iron holder (include cleaning ball)

Power cord

Grounding wire

Instruction manual

10

iron.If the resistance of “C” is bigger than the resistance value listed

below, please clean and remove the oxide with sand paper and steel wool.

Excel 2 High frequency iron resistance

A

B

C

Between pin 4 and 5(heater)

Between pin 2 and pin 3 (Sensor)

Between high frequency iron and pin 1

<

Ω(

normal

)

10

<

1

Ω(

)

normal

<

10

Ω(

normal

)

Damage of accessories of heater and sensor

Dismantle the high frequency iron

1.

Unfasten the screw anticlockwise

①

, pull out the steel jacket

②

and

soldering tip

③

2.

Unfasten the nut anticlockwise

④

,pull out the nut from the soldering

iron.

3.

Take out heating elements

⑤

and connection cord

⑾

from soldering

iron

⑧

4.

Take out the heating elements from the soldering iron with heat-

resistance pad instead of metal tool(such as pliers).

Measure the resistance of heater and sensor

Measure the resistance when the temperature of soldering element

recovers to room temperature, please refer to Excel 2.

Check after replacement

After repalcement of heating elements, please proceed with the following

items:

Measure the resistances between pin 1 and pin4/pin5, pin1and pin2/3, pin

4and pin2/3, the resistance should be ∞, if resistance is not ∞ , the heater

may touch sensor or external cover, the station won't work.

2.Measure the resistances of “a” “b” and “c” to make sure the lead is not

distorted and the grounded wire is connected correctly.

High frequency iron lead damage

Measure the power of high frequency iron as below two methods,

1.Turn on the power, Try to shake or enwind the every parts of connection

cord. If LED indicator light of heater flashes, the connection cord should

be replaced.

2.Measuer the resistance between pins of iron plug and lead wires at the

socket.Pin1-Shilding wire, Pin2,3-sensor, Pin4,5-heater.The resistance

value

should

be

0

Ω ,

the

resistance

is

over

0

Ω

or ∞, replace the

wire.

Summary of Contents for 3200

Page 2: ...Optional Tips 12 ...