Plumbing Considerations

The control system can be installed wherever it may be convenient, however, it is supplied

with a pressure switch. Therefore, it is only possible to install the heater on the pressure

side of the of the plumbing system. (If you find it necessary to install the heater on the

suction side of the plumbing system, please contact Hydro-Quip for further information).

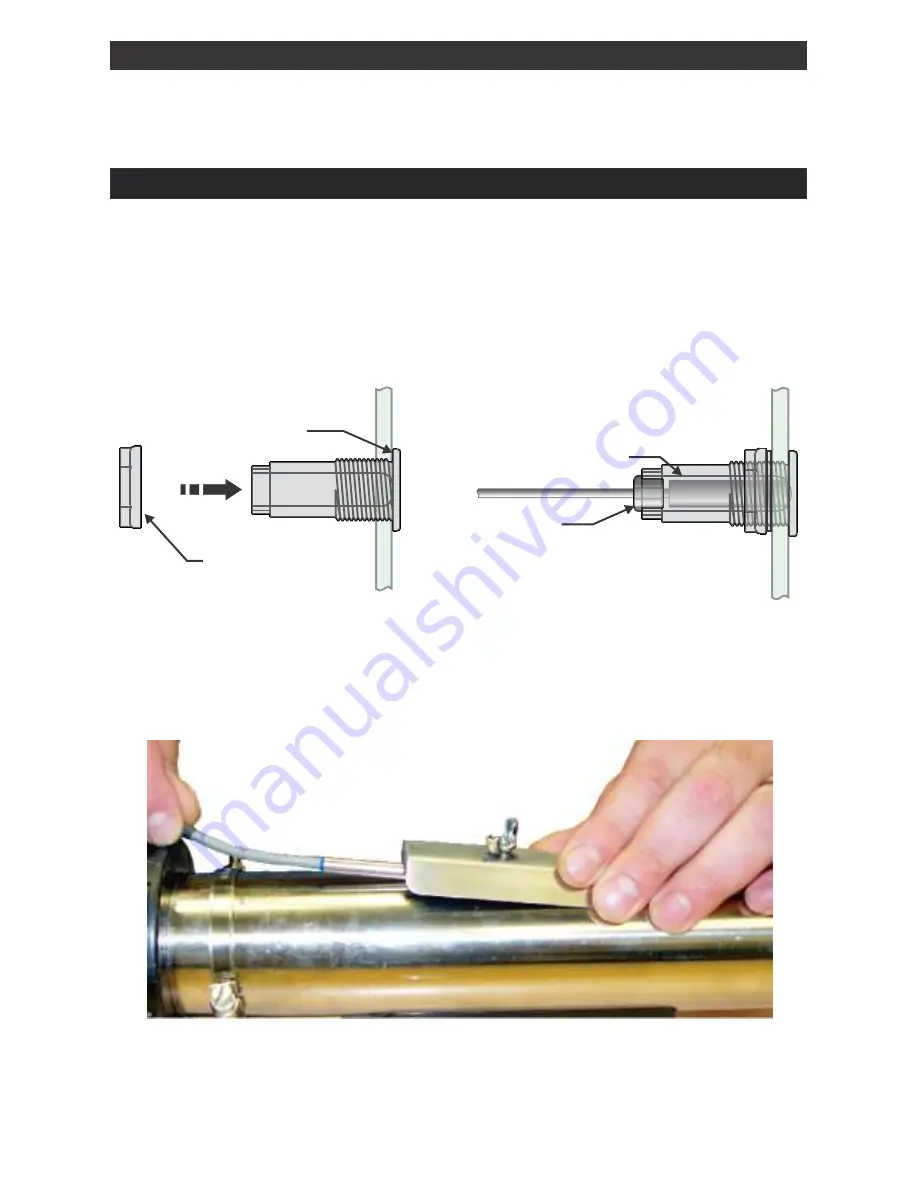

Option #1 Drywell:

The “U” Series fixed heater configuration comes with a 8’

temperature sensor to replace the existing temperature sensor for “Drywell” housings.

If the existing placement of your temperature sensor does not allow for an accurate

temperature reading, a drywell may have to be installed in the spa wall. Once a location

has been chosen, cut a 1 1/8” hole (cut from inside the spa). Clean excess debris from

around the hole. Use a water resistant silicone applied to the sealing surfaces and insert

the drywell into the hole. Tighten the drywell nut ( DO NOT over tighten). Insert

temperature sensor into drywell and insert grommet as shown below. Allow silicone to

cure for 24-hours.

Spaside Control Operation

Temperature Sensor Installation

9

Option #2 Heater Housing:

The “VS” / “US” Series heaters comes with 1/4” sensors

located under the plate. To install the sensor, loosen the wing nut and slide the sensor

under the plate until it becomes no longer visible. Once the sensor is install under the

plate, tighten the wing nut to ensure the sensor is secure. If you wish, you can order the

10’ x 3/8” temperature sensor to replace the existing temperature sensor for “Drywell”

applications.

Option #3 Using your existing sensors:

If you are replacing an existing Balboa Lite

Leader system, you may use your existing sensors. This will be optional in applications

with the temperature sensor installed in a “Wetwell” application or unable to gain access

to the temperature sensor.

SEALING SURFACE

SEALING SURFACE

GROMMET

TEMPERATURE

SENSOR

SpaDepot.com