INITIALIZE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Test Comm Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Initialize All Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Initialize Changes Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

PARTS DEPARTMENT USER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Creating a New Work Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Work Order Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Tanks and Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Dispense Keypad Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Meter Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

WORKSHEETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

INTRODUCTION

The Fusion 2.4 Fluid Management System has been designed to control and monitor the consumption and

inventory balances of automotive fluid products with minimal installation and programming costs.

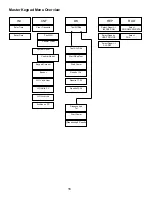

The Distributed Control System (DCS) hardware consists of one Master Keypad and at least one Dispense

Keypad as well as at least one radio frequency (RF) electronic preset meter. The Master Keypad manages

serial communication to the PC and RF communication to the Dispense Keypads in the system. The system

verifies the operator’s pin number and validates the work order number, fluid quantities and the valid hose/

meter�

The Master Keypad can communicate with up to 36 Dispense Keypads that can be positioned to support the

workflow of the facility the best way. Each Dispense Keypad can control up to 24 meters, with a maximum of

250 meters per system. The system supports up to 16 tanks and 16 fluids as a part of the system configura

-

tion. The system supports 250 unique operator IDs and pin numbers.

The system uses direct sequence spread spectrum RF technology to prevent communication problems with

other equipment in the facility. The RF system will look for a clear channel for transmission to insure that there

is reliable communications at all times. Communication distances are typically up to 300 feet with unob

-

structed line-of-sight. A remote antenna is available for situations where multiple buildings are involved in the

installation or obstructions hinder RF transmission/reception.

The PC is used to configure the system, maintain system data and enter work orders. The service desk would

use the PC to enter a work order selecting the fluid and quantity required. The PC can stack as many work

orders as required, limited only by the disk storage space of the PC. There is no need to predetermine where

the work is going to occur, this allows the flexibility to service a vehicle at any open bay and select a meter

when the work is going to be performed. When the work order is going to be performed, the service personnel

simply enters their pin number, work order and hose that is going to be used at the Dispense Keypad. Option

-

ally, the system can be configured to allow service personnel to freely enter work orders, without them first

being entered at the PC.

There are a number of system utilization reports by user, fluid type, tank or meters available for the system’s

management�

A unique, patented feature of the system is that the RF meter’s dispense trigger is locked until an authoriza

-

tion from the keypad is received. After the dispense batch is completed, the user can top off if more fluid is

required. The actual dispensed amount is sent back to the keypad and the meter returns to the locked status.

Additionally, the meter can be installed on portable dolly systems offering control and monitoring of high-cost

lubrication products.

3

Summary of Contents for Fusion 3110-027

Page 4: ...4 System Overview...