7

Revision Log:

Rev. E - Added o-ring and 831335 kit

Rev. F - Changed from 3/8” NPT to 3/8” NPS on outlet port.

Rev. G - Note about washer (item 32).

Rev. H - Removed semi-automatic tip models and changed part number for automatic tip to 3332-086.

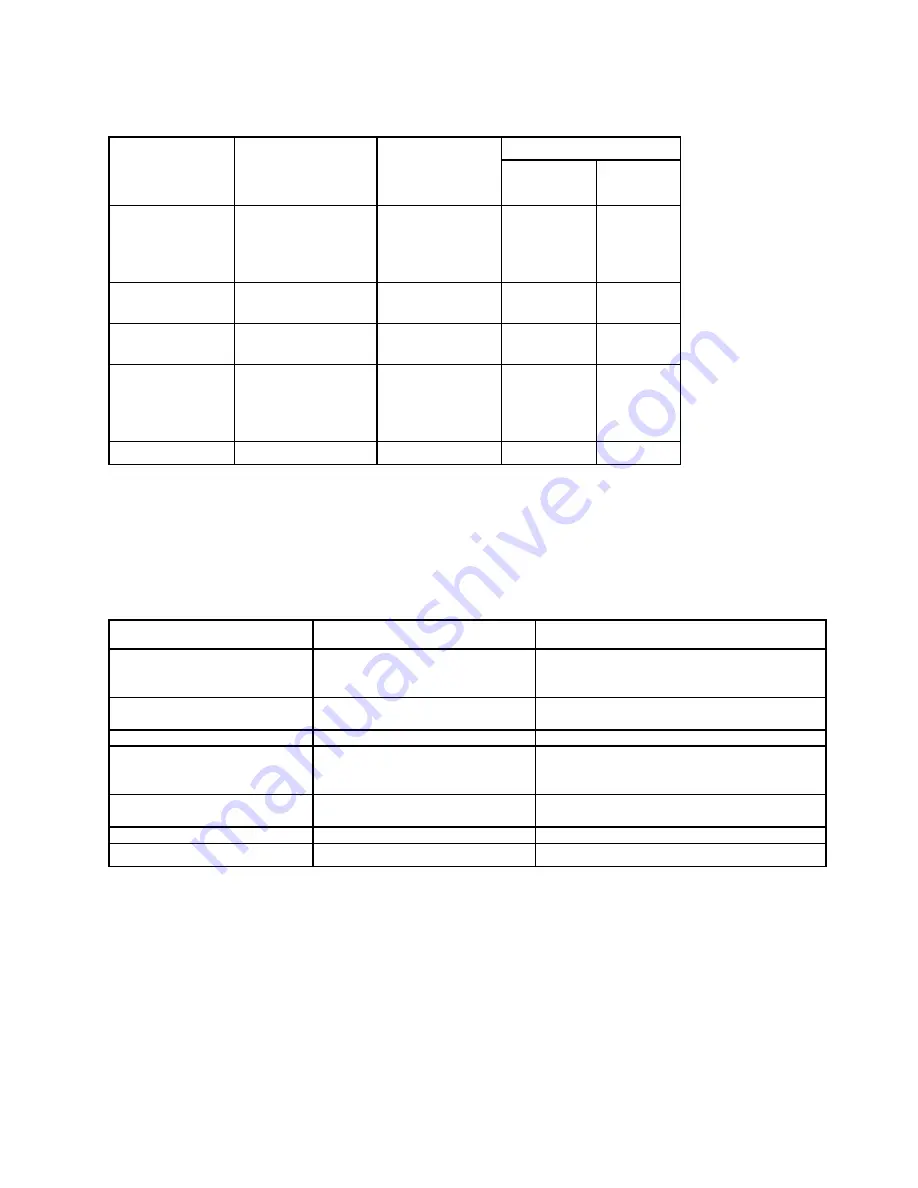

TROUBLE

CAUSE

REMEDY

No fluid passing through the

A. Blocked strainer

A. Clean or replace strainer (47)

meter

B. Dirt particles jamming the rotors B. Dismantle meter assembly and clean

C. Damaged plunger seal

C. Replace damaged plunger seal (40)

The meter is not registering

Damaged Mechanical Module

Replace Module (item 25)

fluid output

Constant oil leak from the tip

Damaged plunger seal

Replace plunger seal (check for damage)

Intermittent drip from the tip

Dirt in the tip

Remove the tip and blow out any dirt particles,

replace if necessary

Tip not closed (semi-auto tip)

Tip must be manually closed

Oil leak from the lever

Damaged o-rings

Replace damaged o-rings (item 33 & 31)

assembly area

Low flow rate

Blocked strainer

Replace strainer (item 47)

Oil leaking from the swivel inlet

Damaged o-ring or swivel

Replace o-ring (item 48) or swivel (item 46)

* 806895 (-112) o-ring included with extension.

Outlet

Extensions

Model

Number

Nozzle / Tip

Extensions

Before 5/03

3/8” NPT

After 5/03

3/8” NPS

Rigid

3330-037 Qt.

3330-040 Lt.

3332-086

829648

831471

plus seal

-

ing nut

831470

Flex

3330-038 Qt.

3330-041 Lt.

3332-086

829973

831469*

Flex 90

0

3330-039 Qt.

3330-042 Lt.

3332-086

830276

831429*

Straight

3330-060 Qt.

3330-061 Lt.

3332-086

81334 plus

jam nut

831333

831472

plus seal

-

ing nut

831470

9” Flex

3330-053 Lt.

3332-086

830107

831473