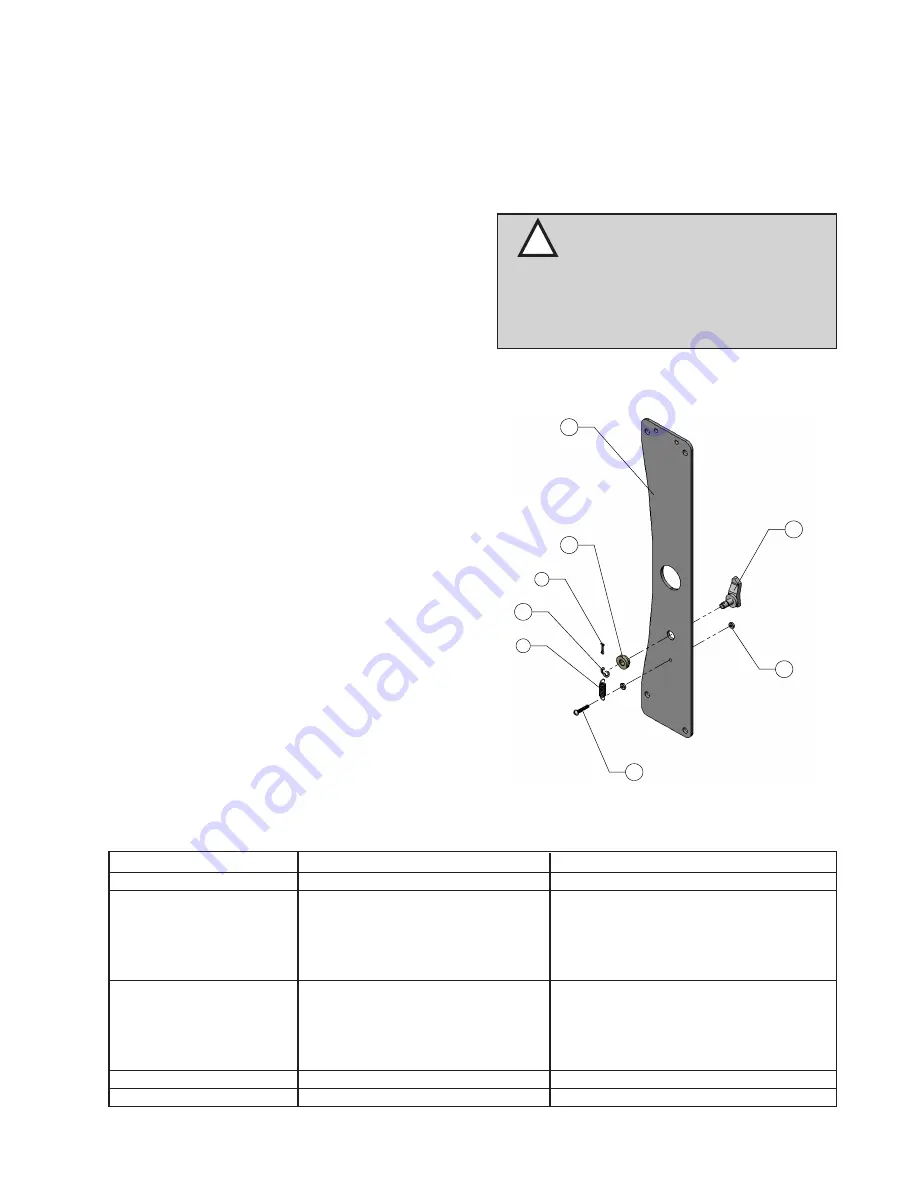

9

25

27

34

10

1

26

16

8

Maintenance

Stop Pawl Replacement:

1. Allow the hose to retract as far as the hose

stop to remove tension from the power

spring and to be sure that the stop pawl is

not engaged with the ratchet.

2. With the stop pawl assembly free to be

moved by hand, remove the cotter pin (1),

spring (8) and snap ring (26). Once this has

been done the complete assembly can be

removed.

3. Item (27) bronze bearing will need to be

knocked out of the upright (10), using a

punch and hammer.

4. With the stop pawl kit in hand replace the

bronze bearing by pressing the new bearing

into the upright (10).

5. Apply a light coat of grease to the stop pawl

stud (25), reassemble by placing the stop

pawl stud (25) back through the bronze

bearing (27) and insert the snap ring (26)

into the groove on the shaft of the stop pawl

stud (25).

6. Replace the spring (8) and cotter pin (1) with

the new ones provided in the kit.

7. Check the stop pawl assembly by hand for

free movement. The stop pawl assembly

should not stick or drag and it should return

to its central position each time it is moved

off center.

CAUTION:

Never alter or modify

any parts of this reel. Doing so may cause

damage to reel and/or personal injury.

Always use genuine Balcrank replacement

parts.

NOTE:

Number with “*” is a component of the

stop pawl repair kit # 811128.

!

Figure 8

Stop Pawl Replacement

NOTE:

If the assembly does not appear to

be returning back to its neutral position, the

spring tension may need to increased. You

can increase the spring tension by bending

the cotter pin closer to the stop pawl shaft

which will stretch the spring slightly.

Trouble

Probable Cause

Remedy

No spring tension

Power spring broken (item 13)

Replace power spring (see page

7)

Low or high tension

Lost wraps or too many wraps of

on hose

hose on reel

Hose will not retract

Stop pawl lock-up

CAUTION:

Wearing heavy leather

gloves, firmly grab the outside edge

of the spool with both hands. Release

the tension on the stop pawl by hand

for one or two revolutions.

Stop pawl will not engage Spring broken or unhooked

Replace or repair (item 8)

Swivel leaking

Worn o-rings, block, or packing.

Replace swivel (item 32)

Troubleshooting Guide

Add or take off wraps of hose

by pulling hose on reel down

just enough to allow stop pawl to

engage ratchet. Now wraps can be

added or taken off as needed.