TABLE OF CONTENTS

Cover ...................................................................... 1

General Safety Information..................................... 2

Technical Data & Notes .......................................... 3

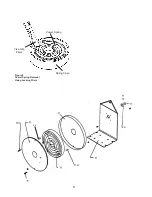

Mounting Dimensional Data ................................... 4

Installation ........................................................4 & 5

TEChNICAL DATA

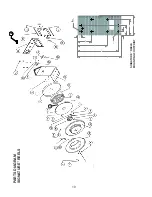

Maintenance ........................................................ 6-9

Parts Listing ...........................................................11

Warranty ............................................................... 12

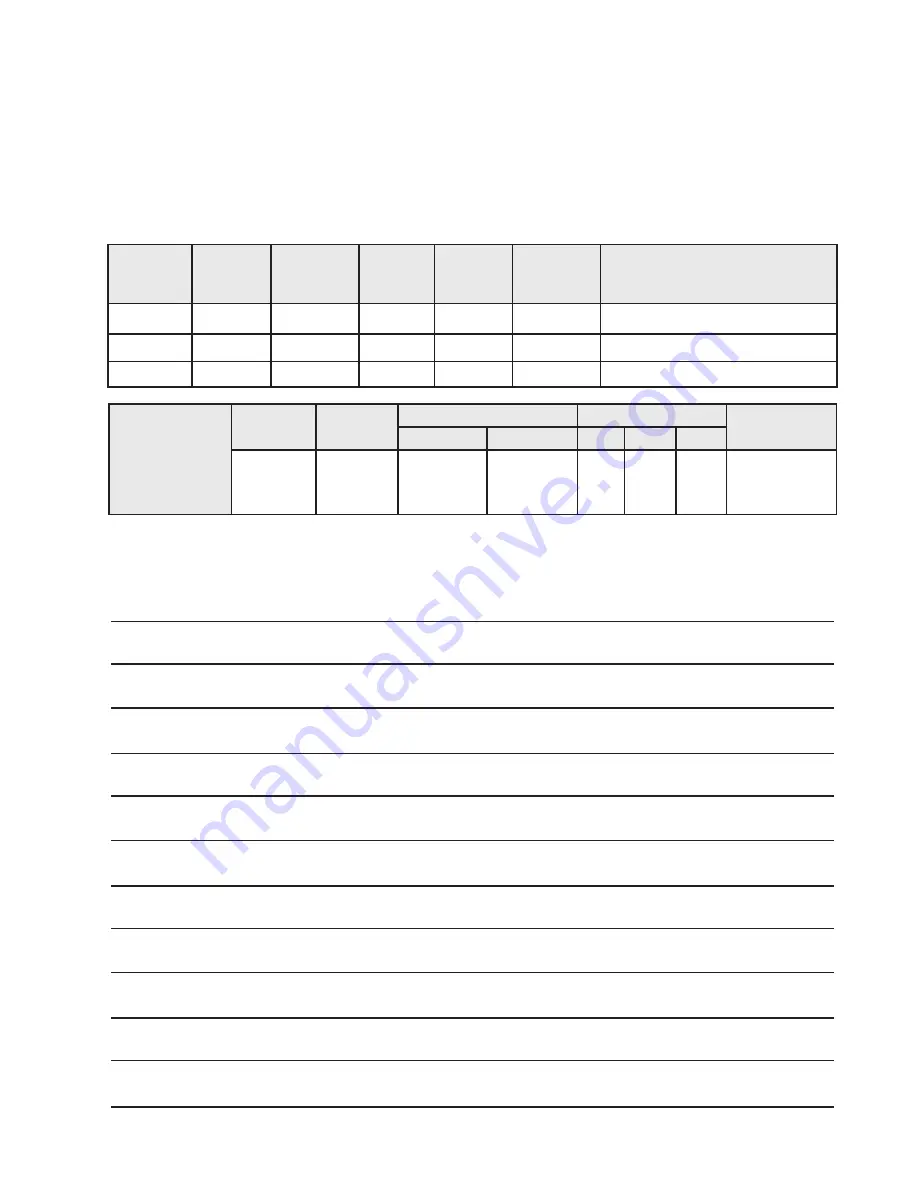

Model No.

hose

Size

Maximum

Working

Pressure

Outlet

hose

Inlet

hose

Bare Reel

Wetted Parts

2400-007 16’ X 3/4”

150 psi

8569-016 8562-003 2400-006

Stainless Steel, Viton

2400-008 20’ X 3/4”

150 psi

8569-020 8562-003 2400-006

Stainless Steel, Viton

2400-009 30’ X 3/4”

150 psi

8569-030 8562-003 2400-006

Stainless Steel, Viton

Bare Reel

(1)

Model

Bare Reel

W.P. (psi)

Thread Size

Reel Dimensions

Shipping

Weight

Inlet

Outlet

L.

W.

h.

2400-006

150 PSI

3/4” BSPP 3/4” BSPP 16”

8”

17.5”

46 lbs.

(1) DEF Reels come in blue powder coat only.

3

Notes